ERP System Reengineering and MES Implementation

A digital transformation success story for the US apparel manufacturing industry

A prominent “Made in USA” Apparel Manufacturer was seeking a digital transformation partner to enhance efficiency, agility, and profitability. Outdated MES and ERP systems were hampering efficiency and affecting business growth. So, the client needed a scalable solution for actionable reporting and real-time data visualization. To facilitate their pursuit of digital manufacturing excellence, we assisted them with apparel industry legacy MES and ERP software modernization.

Capability

Digital Manufacturing

Industry

Manufacturing

Country

USA

Challenges

Siloed data and lack of real-time insights adversely impacted the ability to respond to market shifts.

Lack of security updates exposed systems to potential breaches and unauthorized access.

Legacy technology was unable to keep up with modern demands and resulted in slower processing speeds.

Compatibility issues with newer devices and software versions, hindered user adoption.

Limited or no support from vendors for troubleshooting issues in obsolete solutions.

Outdated UI/UX designs failed to meet the expectations of modern users, leading to user dissatisfaction.

Tactical Approach

In our collaborative journey of digital transformation in manufacturing, we navigated the shift from legacy technologies like Microsoft Excel with VBA, MVC, and SQL to emerging technologies like NET 5.0, Angular, and Material Design. Our team strategically leveraged emerging digital technologies and data-driven processes to drive sustainable growth. This involved:

Development of an MES

Migration to Azure Cloud

We facilitated the successful transition of a legacy Windows application with limited VPN access to a dynamic cloud-based environment. This enabled the sales professionals to swiftly capitalize on opportunities, ensuring the client’s sustained performance and competitiveness.

Shipping Workflow Improvement

We optimized box management and integrated new shipping partners to enhance the shipping process. Our approach employed automated tracking for shipping boxes. This reduced errors and accelerated order fulfillment, leading to greater operational transparency and better customer satisfaction across the delivery cycle.

Power BI Integration & Data Visualization

We leveraged Power BI for its data visualization capabilities. This integration allowed real-time access to key business metrics for stakeholders to make data-driven decisions with granular insights into business operations. Additionally, we implemented reporting capabilities within the new system, allowing users to generate custom reports targeting specific KPIs.

Integration and Connectivity

Seamless integration and connectivity are at the core of our MES solution. We facilitated interoperability with existing enterprise systems, such as ERP and SCM, through standardized interfaces and APIs. By enabling bi-directional data exchange and workflow orchestration, our solution ensured end-to-end visibility and synchronization across the manufacturing ecosystem.

Production Workflow Improvement

We expanded the production workflow by adding new work centers and modules to better manage production queues. We also automated manual processes to enable real-time data capture and more efficient task assignment. This gave production teams deeper operational insight, improved resource allocation and clear visibility into inefficiencies for continuous improvement.

Quantifiable Outcomes

Realizing the importance of adapting to evolving business needs and scaling operations for future growth, our MES solution was designed to provide flexibility. Our involvement in the legacy ERP & MES system modernization for apparel manufacturer ensured their systems were compliant, secure, efficient, and agile. Here are the key features and benefits of the solution:

Enhanced Supply Chain Visibility to Mitigate Risk

Estimated Delivery Date Calculation

With our ERP manufacturing execution system, accurate estimation of delivery dates became effortless. We integrated predictive analytics and historical data to forecast production lead times, considering factors such as material availability, production capacity, and order complexity. Precise delivery date calculations allowed the client to better manage customer expectations and optimize resource allocation.

Inventory Optimization to Improve Stock Management

The MES and ERP integration enabled precise inventory management while minimizing excess stock and reducing carrying costs. To further enhance accuracy, we implemented a Cycle Count Module specifically designed for the warehouse team. This feature facilitates regular, systematic inventory checks without requiring full physical counts and reduces disruption to daily operations. By integrating cycle counts into the workflow, warehouse teams maintain high inventory accuracy, improve stock visibility and streamline reordering processes.

Production Planning and Scheduling

MES development solution optimized production planning and scheduling processes for enhanced efficiency and productivity. Leveraging advanced algorithms and real-time data integration, we enabled dynamic production scheduling, resource allocation, and workflow optimization. This ensured seamless coordination between production activities, minimized downtime, and maximized throughput.

Outcomes

reduction in response time to market changes

Technologies Used

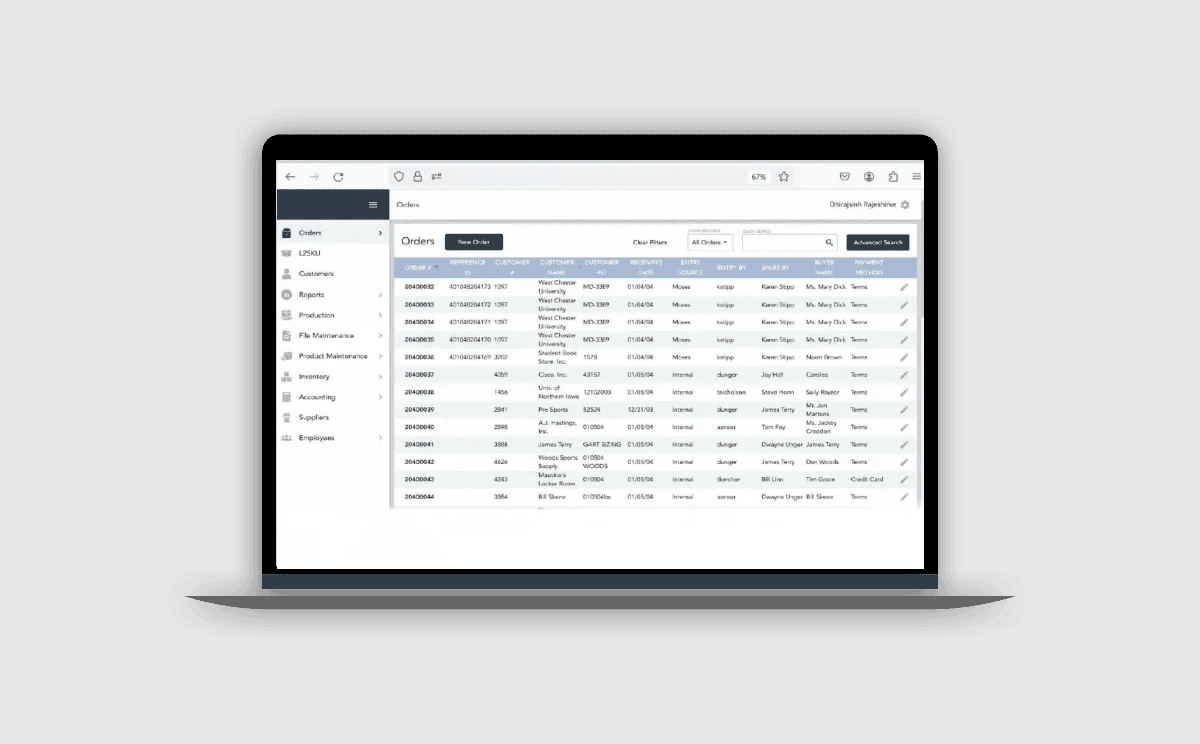

Project Snapshots

Recent Case Studies

Optimize your cloud infrastructure, implement robust solutions, and stay ahead of trends with our resource hub.