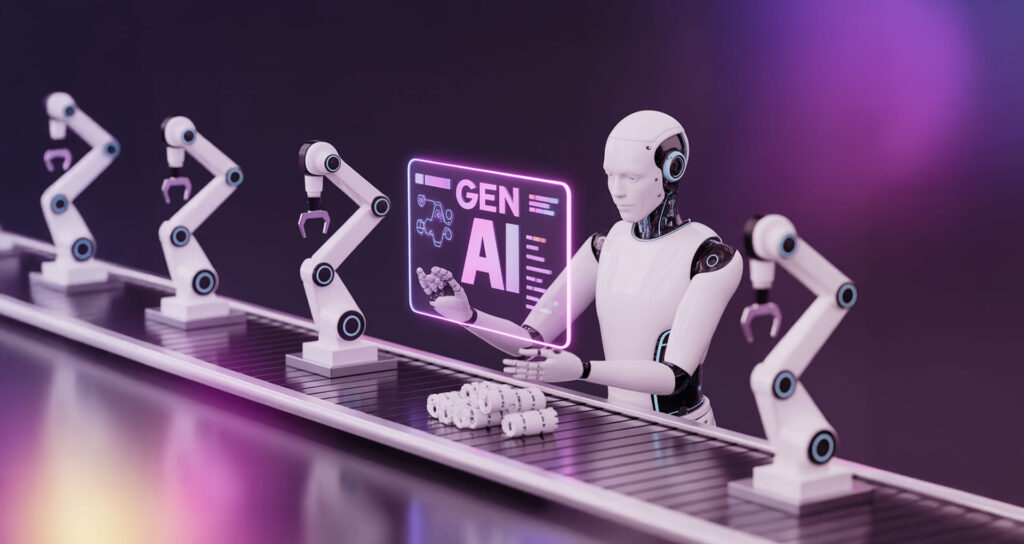

Digital Manufacturing Solutions

We provide tailored digital solutions for industrial equipment providers and connected device manufacturers, optimizing production, operations, and enterprise platforms to accelerate Industry 4.0 transformation.

Unlock Manufacturing Excellence with Custom-Engineered Industry 4.0 Solutions

Off-the-shelf tools rarely match the lived reality of a plant where legacy controllers sit beside cloud dashboards under tight audit pressure. When software can’t flex, engineers spend more time patching spreadsheets than lifting throughput.

We at Rishabh Software leverage AI-powered ERP agnostic solutions to digitize operations by modernizing legacy systems, customizing our pre-built PoCs for digital factory solutions, or building a tailored solution from the ground up. As an experienced digital manufacturing company, we begin by mapping the movement of materials throughout your facility, then ideate and develop digital solutions that optimize these flows. You get tailored, targeted solutions like plant-specific MES, ALD, EHS Compliance, and more -all built for seamless integration with your existing environment.

These custom-developed digital manufacturing solutions, powered by IIoT, cloud, data analytics, AI/ML, and generative AI, enable smarter autonomous processes, minimize downtime, and boost worker productivity.

Digital Manufacturing Segments We Serve

With our tech expertise and strong industry focus, we assist manufacturers in driving transformation at every level of their value chain. From the shop floor to the top floor, we help you digitally transform your manufacturing operations by developing tailored solutions.

Industrial Machinery

We optimize factory operations using technologies like IoT and AI for predictive maintenance. This reduces downtime, lowers costs, and boosts machinery performance, ensuring smarter workflows.

Contract Manufacturing

Our digital solutions enhance efficiency and cut costs by automating order tracking, inventory management, and supplier collaboration for seamless operations.

Batch Processing

We improve batch processing with automation, real-time monitoring, and predictive analytics, minimizing waste and downtime while maintaining consistent quality.

Food and Beverage Manufacturing

We implement traceability and quality control systems to ensure safety, reduce waste, and maintain batch consistency with real-time monitoring and automated compliance tracking.

Custom Digital Manufacturing Solutions We Offer

Experience digital excellence from early discovery through live rollout, powered by a blend of manufacturing domain insight, software-engineering rigor, and modern Industry 4.0 technology.

Real-time production control, built to match the way your plant actually runs

Our customizable, cloud-based MES connects ERP systems with on-floor controls to deliver real-time visibility across machines, materials, and production flow. Designed to work within your existing infrastructure, it supports plant-specific logic and dashboards, empowering teams with the data and control they need. From preventive maintenance to shift-level performance analysis, the system adapts to your process environment and scales with evolving production demands.

Key features of this customizable solution include:

Equipment & Machinery Control

Work-In-Progress (WIP) Tracking

Inventory Management

Production Tracking and Scheduling

Quality Management

Real-Time Data Analytics

Integration and Connectivity

Resource Management

Personnel Management

Product Tracking

Performance Analysis

Digitize assembly operations with system-aware process twins and contextual guidance

Assembly processes are rarely uniform, which is why we built this solution to reflect the specific material flows of your line. It creates a digital twin of the assembly environment, which facilitates real-time monitoring, in-process quality validation, and step-by-step worker guidance on connected displays. Integration with MES and ERP systems ensures data consistency while reducing paperwork and errors.

The key components of this comprehensive approach can include:

Assembly Line Monitoring & Control

Quality Check and Assurance

Digital Work Instructions

Worker Assistance

Inventory and Materials Management

Maintenance and Equipment Monitoring

Reporting and Analytics

Integration and Connectivity

Reduce downtime and extend asset life with predictive, configurable maintenance workflows.

Our factory maintenance platform empowers you to optimize maintenance processes and efficiently allocate resources through predictive maintenance capabilities, IoT-enabled sensors, and remote diagnostics. Teams get real-time alerts and can fix issues before they cause downtime. Remote diagnostics make troubleshooting fast and easy. This customizable system enables you to schedule maintenance more effectively and utilize resources more wisely. You save money and keep production on track.

The key capabilities of this digital manufacturing solution include:

Maintenance Management

Asset Management

Preventive Maintenance

Predictive Maintenance

Work Order Execution

Breakdown Maintenance

Maintenance Reporting and Analytics

Integration and Connectivity

Ensure compliance, safety, and responsibility with a single platform.

Our EOHS solution gives you a single, cloud-based platform to manage all aspects of environmental, occupational, and health safety. Powered with automated compliance reporting, risk assessment tools, and mobile access, our cloud-based workplace health and safety management software lets you schedule and document safety inspections, manage PPE stock, and keep up with employee training and certifications. You can configure features for multiple sites, integrate seamlessly with your current systems, and strengthen emergency preparedness to improve efficiency, reduce risk, and meet compliance requirements without complexity.

It includes the following key features:

Compliance Management

Incident Management

Risk Assessment

Training and Certification

Safety Inspections and Audits

Emergency Preparedness

Safety Data Management

PPE Inventory and Stock Management

Secure Document Storage

Multi-site Configuration

System Integration

Optimize process line productivity with intelligent automation

Our custom-developed process line engineering solution caters to the modern chemical, pharmaceuticals, nutraceuticals, and processed foods manufacturing industries. Developed with our Safety Engineering expertise, the platform delivers instant process visibility and control from anywhere by integrating real-time sensors, gateways, and loggers with powerful cloud and mobile apps. Advanced AI and ML analytics make it easy to optimize productivity, enhance quality, and reduce resource waste, while robust safety engineering and end-to-end traceability ensure compliance and a secure work environment. You gain streamlined operations and effortless regulatory adherence with unified integration across ERP, MES, EHS, and OHS systems.

Revolutionize your process-line manufacturing operations with the following features:

Raw Material Management

Batch Management

Process Monitor & Control

Quality Control & Assurance

Maintenance Management

Environmental Monitoring & Compliance

OSH Management

Integration & Connectivity

All-in-one solution to eliminate stock disruptions and accelerate order fulfillment

We have built a gas cylinder distribution and tracking solution that streamlines your gas distribution operations with real-time tracking and automated stock management. You can efficiently manage your entire supply chain and fleet of gas cylinders by leveraging a user-friendly mobile app and comprehensive web dashboard. It comes with an intuitive interface and robust features to ensure seamless coordination across procurement, stock monitoring, and delivery processes.

Benefit from real-time tracking, efficient order fulfillment, and comprehensive customer support leveraging the following capabilities:

Bulk Order Management

Industrial and Domestic Sales

Stock Tracking

Create OTC or Line-sales Order

Bulk Delivery Assignment

Track Payments and Deposits

Real-time KPI Data

Data Analysis and Sharing

On-demand Invoicing

Mobile-first interface for field operations

Integration with GSM communication systems

Digital Manufacturing Success Stories

Explore how our digital expertise helped manufacturers leap into the future of production.

ERP Modernization

MES Implementation

ERP System Reengineering and MES Implementation

Reporting Software

Production Planning & Reporting Software Modernization

Digital Manufacturing Services to Accelerate Digital Transformation

The success of our digital manufacturing solutions lies in our ability to integrate real-time data and insights seamlessly into your supply chains and products. With our key offerings, we automate your manufacturing value chain to swiftly adapt to economic shifts on a local or global scale.

Legacy Platform Modernization

Outsourced Product Engineering

Enterprise Data Analytics & Visualization

Enterprise Data Analytics & Visualization

Enterprise Process Digitalization & Automation

Enterprise Process Digitalization & Automation

Your Trusted Digital Manufacturing Company

Empower your manufacturing value chain through digital innovation with intelligent, interconnected solutions that drive success & efficiency. With a proven track record in Industry 4.0 implementation, we are well-versed in creating smart manufacturing solutions to optimize your workflows and eliminate inefficiencies.

Advanced Technology Integration

Our digital manufacturing solutions integrate connectivity, data collection, advanced analytics & data visualization with your existing IT infrastructure.

Data-driven Manufacturing

Our digital manufacturing services use flexible data modeling frameworks & best practices to augment any platform with advanced capabilities.

AI-Powered Business Intelligence

We integrate AI solutions that drive automated workflows, reduce costs and minimize downtime with Power BI based dashboards, automation & real-time efficiency.

Proven Track Record

We use hybrid cloud, automation, IoT, and AI to provide scalable industry 4.0 solutions that efficiently address your unique challenges.

Global Clients

Explore, Innovate, and Excel in Digital Manufacturing!

Optimize your factory operations, implement Industry 4.0 solutions, and stay competitive with expert insights and best practices.