Rishabh Software developed an IoT-based web solution with integrated analytics for an Asia-based fluid control system manufacturer to enable real-time monitoring of fluid flow, storage levels, and volume, resulting in 24×7 asset visibility, improved production planning, and enhanced operational efficiency.

Project Overview

Our client is a leading manufacturer of fluid control systems with IIoT devices to their global customers. It is in the areas of liquid measurement, fluid control and industrial dispensers. The company was on the lookout for a comprehensive solution to collect and transfer data within an integrated system.

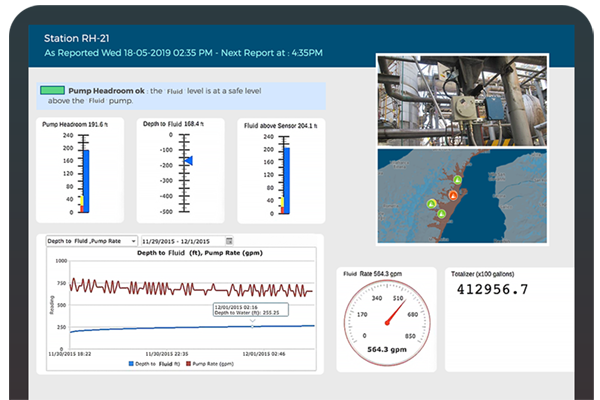

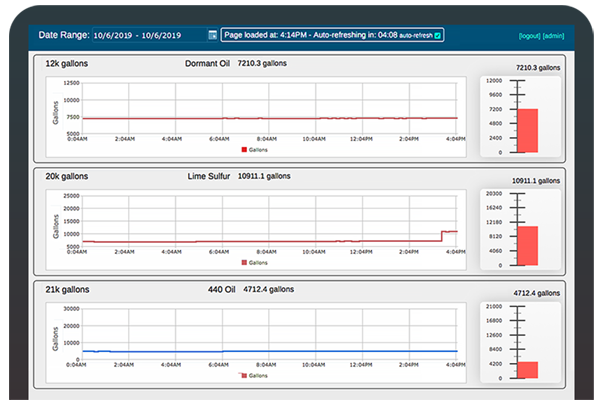

Rishabh Software being an experienced IoT application development company, created an IoT-based Web Solution With Integrated Analytics for Industrial Fluid Management. It would help to measure the data related to fluid flow, volume, storage level and more. A BI-powered analytics system integration helps generate real-time reports. It also offers various visualization options.

Challenges

- Lack of a system to capture and integrate operational data from multiple sensors, instruments and other devices

- The Error-prone manual mechanism for liquid management resulted in wastage of costly liquid

- Unable to handle large volume & velocity of data hurting bottom-line results

- Limited visibility of functions across business operations leading to an increase in the performance gap

Solution

By analyzing their existing operations, we defined a business process for the client. It included tenant registration, subscription, management of master data, user management and ultimately generation of reports through analytics.

Predictive analytics mechanism: End customers can monitor equipment performance, daily throughputs from process units, and weather conditions.

Predictive maintenance: Comparing the above against the ideal data contained in the database. As a result, if any issues occur between the current and ideal state, the application triggers technicians’ alerts on their devices.

Unified platform: The application we created was built using the Laravel Framework to add functionalities that brought in transparency in the overall process. The platform for the business & end customers had 5 modules as part of the integrated portal.

Benefits

- A master control panel with a customized dashboard to access and manage data across business functions

- Automated validation, sorting and versioning of data to ensure quality reporting

- Up to 75% reduction in time spent by resources on routine processes leads to a performance improvement

- 30% more cost savings with predictive analytics for early detection of issues and maintenance requirements

- Increased customer base that resulted in a 40% rise in sales revenue

Customer Profile

An Asian Manufacturer of Fluid Control Systems

Technologies

- Laravel framework

- LAMP (Linux, Apache, MySQL, PHP) stack

- AWS (Amazon Web Services)

30 Min

30 Min