Production Planning & Reporting Software Modernization

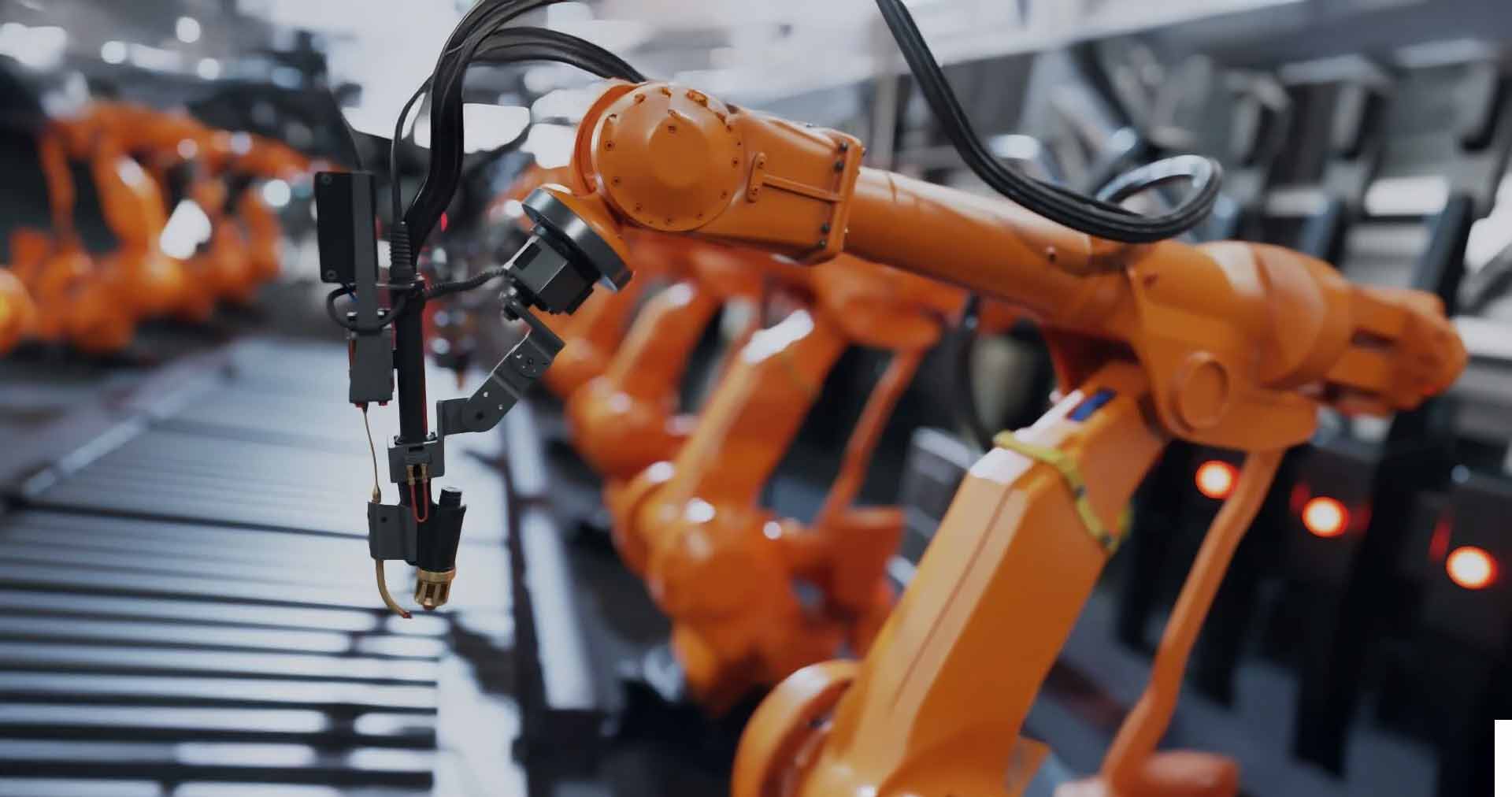

For a US-based Flexible Intermediate Bulk Container (FIBC) manufacturer

The customer’s existing MS Excel-based reporting system was not able to provide the required insights for production planning, leading to increased costs. They needed a unified solution to effectively monitor machinery, human resources, stocks, and orders.

Capability

Enterprise Software

Industry

Manufacturing

Country

USA

Key Features

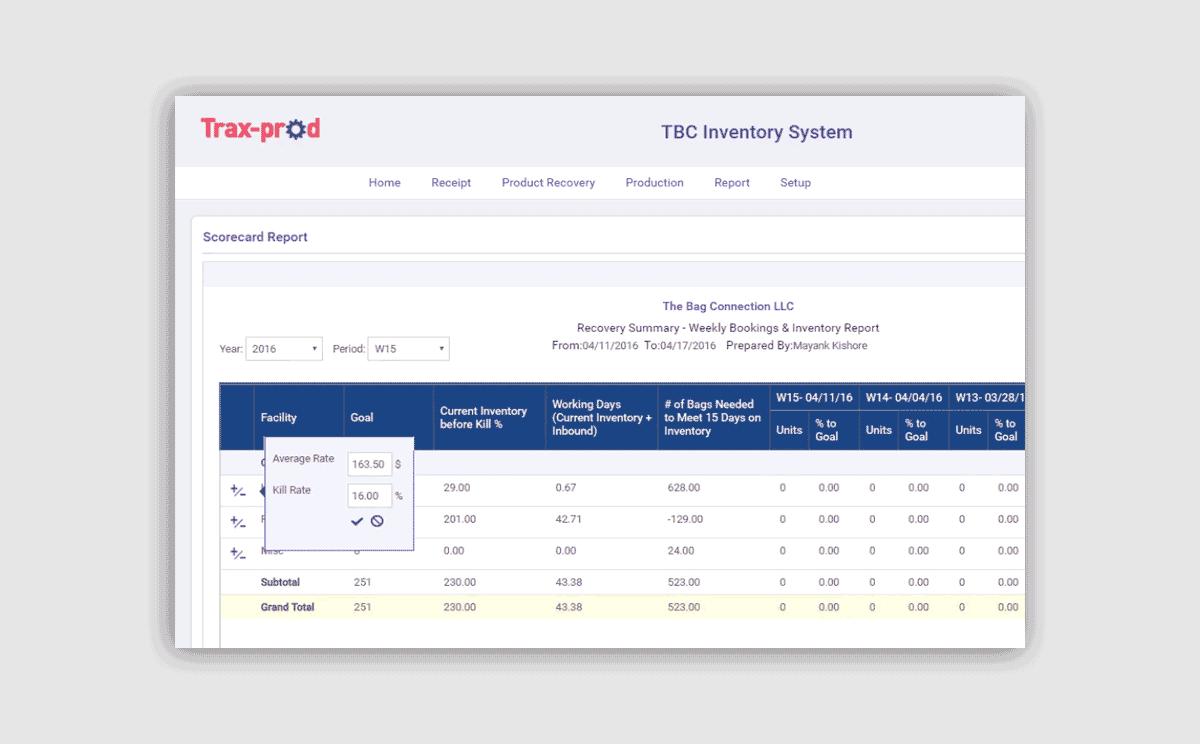

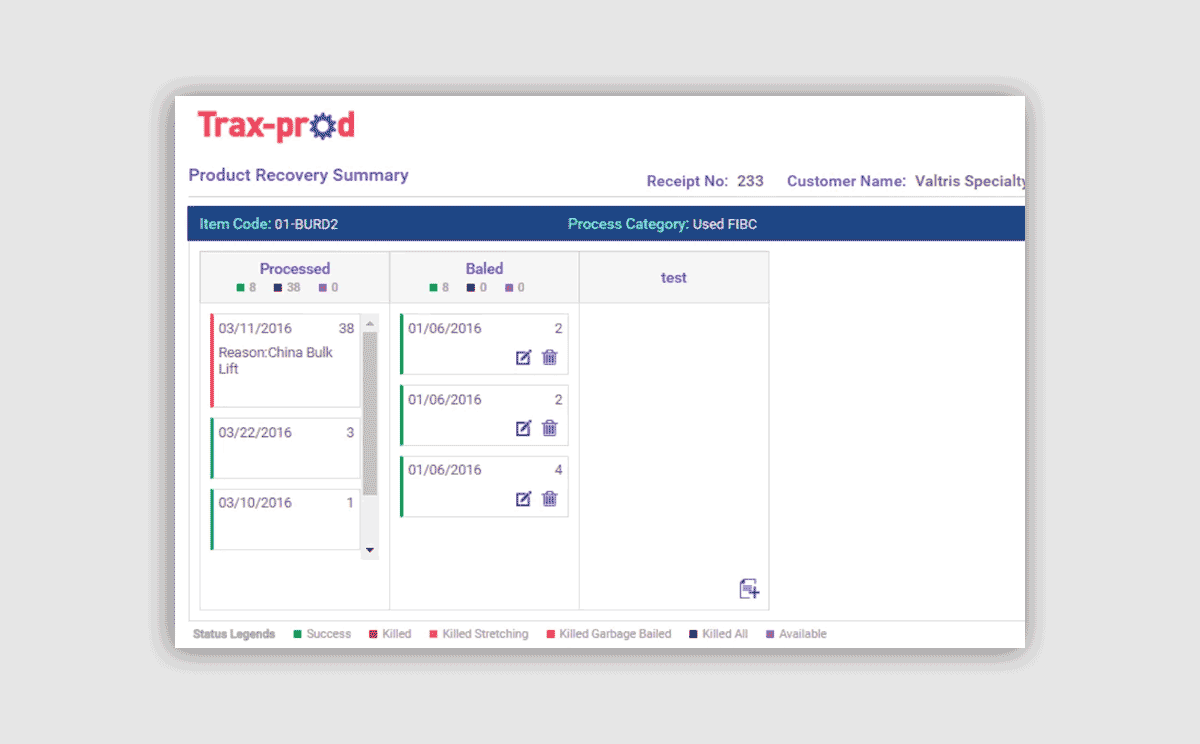

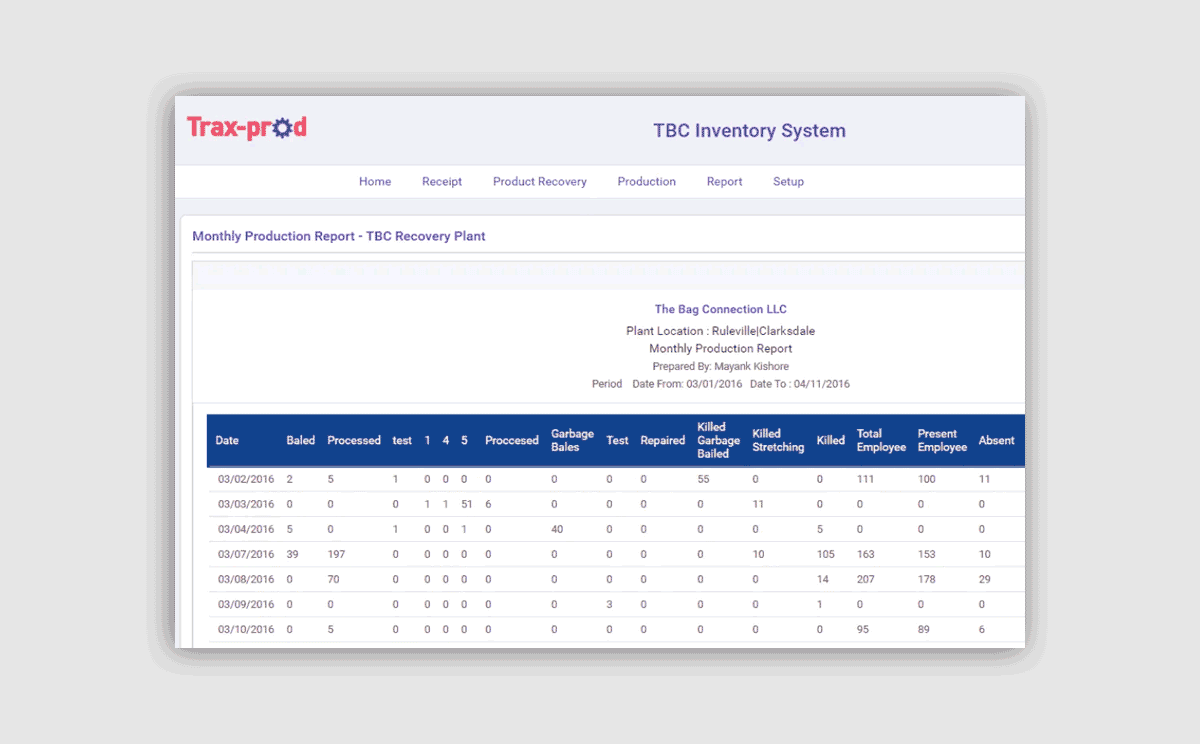

The reporting system helped the manufacturing company track and measure production against the set goal, ensuring better planning and optimum plant capability & resource utilization.

Reporting automation

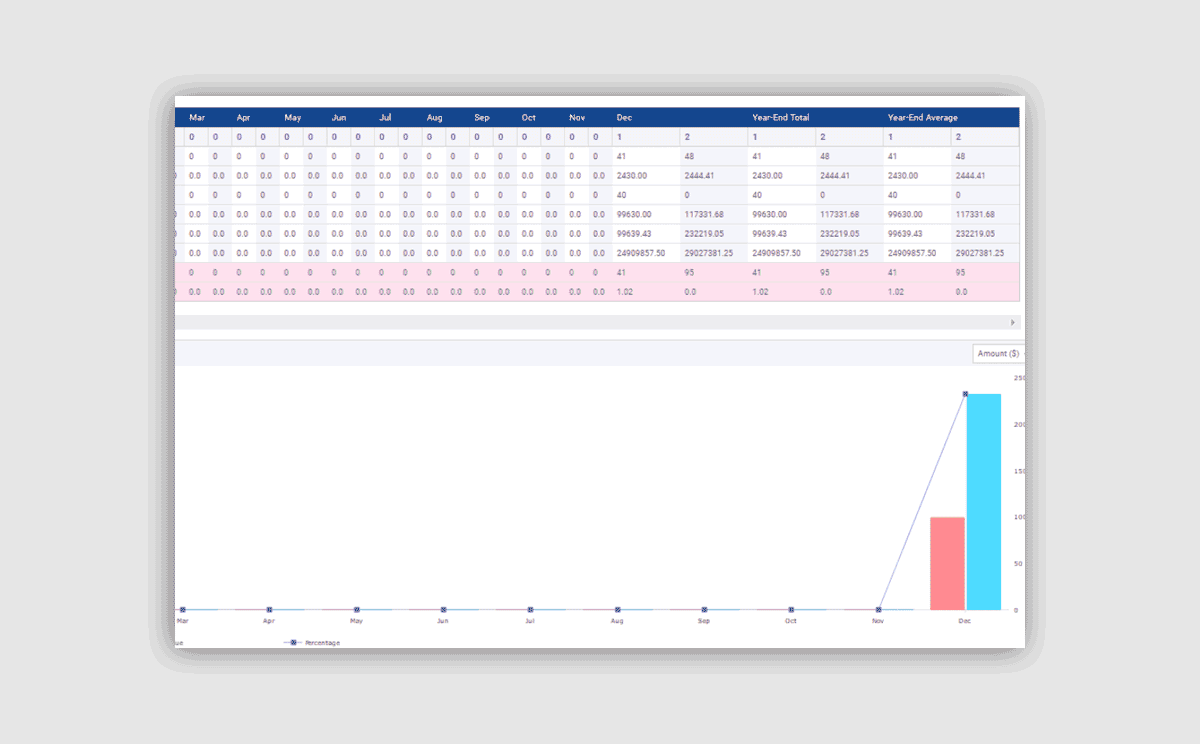

Offers interactive & intuitive reports, analytical reports, charts, graphs, etc., for all production process stages, including raw material expenses, labor costs, etc.

Inventory management

Intuitive dashboard

Unified platform to effectively track the entire production process, from inventory to production & planning to report, with a process-controlled mechanism.

Order projection & mapping

Reporting system helps with demand forecasting by mapping the projected orders and inventory levels.

Challenges

Very high production cost due to no insight on materials required and used

Manual MS Excel style reporting process

Lack of business visibility in terms of production, inventory, and sales plan

Difficulty in resource/labor allocation across the entire production process

Solutions

Our team revamped the Production Planning and Reporting Software to help enable tracking & management of daily production processes, production estimation planning, and streamlining of related processes. The modernization initiative was divided into various phases – from upgrade & integration for accurate tracking & measurement, to improving the application’s interface.

System Upgrade

Our team utilized Microsoft.NET to develop a scalable platform for production planning & reporting. We utilized ASP.NET GridView for easy insertion, deletion, sorting, and paging of record items.

Real-time reporting mechanism

We developed a custom reporting engine component that generates real-time production reports with a custom drag & drop option in Gantt style or interactive scheduling mode based on KPIs and metrics.

Planning & integrations

We designed planning modules to map the client’s production cycle. Our specialist team integrated the developed application with the client’s existing Microsoft Dynamics GP 2010 database. This enabled seamless data extraction & sharing between ERP, accounting, HR, supply chain management & other applications.

User-friendly interface

As the client’s staff was used to Microsoft Excel for performing daily tasks, we designed the interface to keep the look & feel intact and ease up the user experience of the modernized software. We utilized .Net Charts and Bootstrap for UI. Our team has an in-depth understanding & exposure to using Chart Helper to export report data into MS Excel or PDF or share it via email.

Outcomes

Technologies Used

Project Snapshots

Recent Case Studies

Optimize your cloud infrastructure, implement robust solutions, and stay ahead of trends with our resource hub.