The manufacturing industry has stepped into a more intelligent era of operations powered by the transformative capabilities of Artificial Intelligence. Despite the significant progress already made, a remarkable shift is still underway as Generative AI, a subset of Artificial Intelligence, unleashes its immense potential within the manufacturing landscape. Generative AI in manufacturing automates and enhances operations, from instant product design to advanced predictive maintenance and supply chain optimization, which enables strategic decision-making at every step.

According to the research, generative AI is all set to revolutionize manufacturing with a projected market value of USD 6,415.8 Mn by 2033, growing at a remarkable 41.06% CAGR from 2024 to 2033.

In this blog, we will explore more about GenAI use cases in manufacturing, its benefits, challenges, and solutions to address them, and a step-by-step guide to implementing Gen AI in manufacturing.

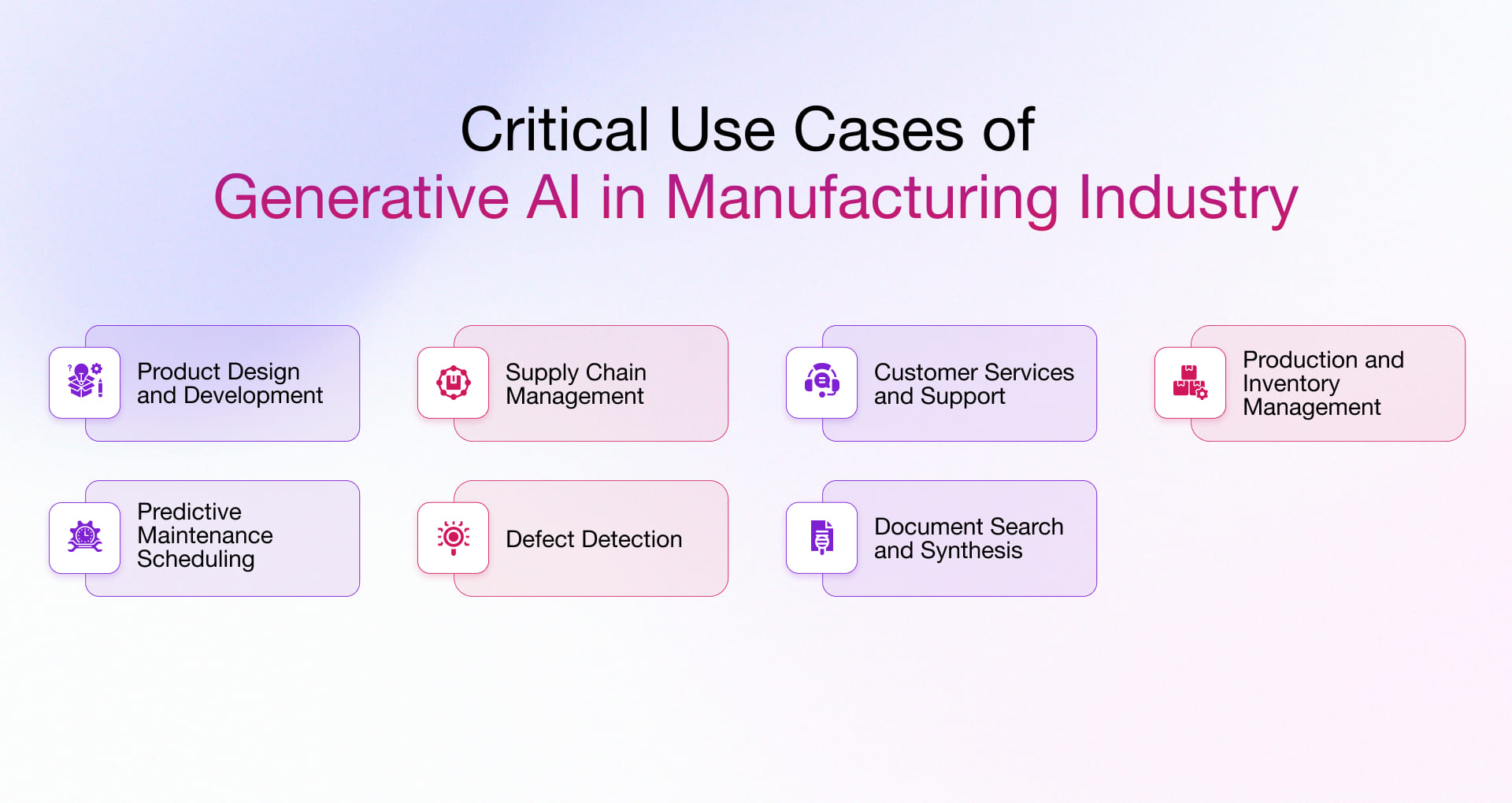

Top 7 Generative AI Use Cases in Manufacturing Industry

The manufacturer operates under never-ending pressure to enhance production processes, optimize supply chains, deliver high-quality products to customers, and quickly adapt to dynamic market trends. To overcome these challenges, the adoption of generative AI becomes incredibly compelling and promotes highly efficient, connected, and smart manufacturing operations.

To cleverly integrate the capabilities of Generative AI in manufacturing, an understanding of its real-world usage in respective operations is crucial. In this section, we have explained the gen AI use cases in manufacturing.

1. Product Design and Development

The manufacturing operation revolves around products, right from designing, manufacturing, and catering. In the core process of developing new products or constantly refining existing ones, generative AI incorporation significantly impacts product engineering through its newfound speed and agility.

Generative AI in manufacturing industry allows product engineers to bypass time-consuming research and focus directly on design by setting critical metrics within the model. GenAI leverages complex algorithms, to provide multiple conceptual design options, automate design optimization, enable precise testing, and helps in achieving future-ready optimal product solutions.

It can generate realistic 3D models and digital twins of products and simulate product performance in design or virtual format, which empowers engineers to closely track, evaluate, and improve designs before manufacturing begins. Thus, generative AI is a comprehensive solution for designing and building robust and custom products by reducing the development cost and accelerating time to market for new products.

2. Supply Chain Management

GenAI’s ability to analyze data and generate content in multiple formats, including text, images, and videos, is revolutionizing supply chain management. Supply chain disruptions encompass significant challenges in manufacturing.

GenAI provides manufacturers with a great extent of visibility across interconnected parts. It also adds value by recommending and selecting suppliers through analysis of various factors, including raw material availability, pricing, potential risks, etc. Additionally, insights from historical interactions with suppliers contribute to strengthening the relationship. it offers real-time insights into ongoing supply chain performance to ensure smooth transactions and improve the decision-making approach.

3. Customer Services and Support

Redefining customer services through the intersection of large language models, generative AI and manufacturing will soon become the new norm. GenAI-powered chatbots and virtual assistants enable quicker interactions with customers based on their unique needs, ensuring immediate resolution of issues, analyzing customer queries, and providing accurate, step-by-step guidance for troubleshooting.

The advancement of LLM allows GenAI to engage with customers in more natural and have human-like conversations. The solution can operate around the clock, responding to reviews and contributing to common customer queries related to orders, exchanges, returns, billing, etc. Additionally, this transformative technology can serve as the representative of the manufacturer to enhance client experience and efficiently manage field inquiries.

4. Production and Inventory Management

Inaccuracies in inventory management and suboptimal resource allocation are the primary reasons of cost overruns in the manufacturing industry. Poor demand forecasting, lack of inventory visibility, and overstocking and out-of-stock situations are key challenges that make the entire process inefficient. Generative AI for manufacturing industry can open the door to smooth and effective production and inventory management by forecasting and smarter inventory management. By modernizing demand forecasting approach with GenAI capabilities, businesses can minimize lost sales due to product unavailability and optimize overall production efficiency.

The GenAI model has the capability to analyze historical sales data, market trends, and other key factors. Based on these insights, it allows manufacturers to instill confidence in their production processes by optimizing them to match the dynamic requirements of stock. GenAI’s role in production planning helps in achieving optimal production schedules, ideal resource allocation, and workflow optimization.

5. Predicative Maintenance Scheduling

The complex structure of manufacturing workflow builds with the integration of even highly complex machines and equipment. In this fast-paced business environment, encountering machine failures and malfunctions is a common challenge that hinders all connected operations and leads to customer dissatisfaction. To address this inefficient distribution that breaks off other area operations, predicative maintenance is proving to be the ideal approach.

The integration of generative AI and IoT in predictive maintenance has the potential to revolutionize how manufacturing businesses approach equipment maintenance. Implementing predictive maintenance strategically can be challenging due to the large volume of data and lack of talent with data science expertise. However, generative AI in manufacturing allows for the addressing of all these challenges by automating data analysis and generating synthetic datasets.

Predictive maintenance powered by Generative AI helps the manufacturing industry minimize downtime and optimize maintenance processes through well-planned scheduling and makes them capable of achieving effective cost-cutting. Gen AI learns from existing datasets and generates new insights, making it a powerful tool for predictive maintenance.

6. Defect Detection

Every manufacturing business struggles with defects, which act as a slow leak in the system, leading to higher costs and reputational damage. Incorporating Generative AI into defect management changes everything for leaders by learning from thousands of past examples and spotting flaws in real time that even seasoned inspectors might miss. Instead of waiting until the end of the line to catch problems, the system flags them early, reducing rework and waste before they snowball.

7. Document Search and Synthesis

Generative AI brings a new capability to one of manufacturing’s most overlooked pain points: navigating the vast universe of technical documentation. For decades, product manuals, service instructions, and purchase orders have been both a lifeline and a bottleneck. Technicians spend valuable hours searching for the one step that will fix a machine; sales teams sift through complex product data just to prepare a quote. The result? Slower operations, higher costs, and frustrated customers.

Here, Gen AI changes the equation. Advanced searching, extracting, and synthesizing information across the product lifecycle, Gen AI in manufacturing gives technicians clear, step-by-step instructions in an eye blink and equips sales teams with instant, accurate quotes. Downtime shortens, decision cycles accelerate, and errors decline. In effect, document search moves from being a hard-to-crack challenge to a low-hanging fruit for productivity gains.

Still, one question remains: if generative AI can already reshape how service and sales teams access information, what’s next? As one manufacturing executive observed, “The opportunity is clear. The challenge is scaling it across functions where complexity is the norm.”

Real World Examples of Implementation of Generative AI in Manufacturing Industry

We always get stuck when it comes to integrating generative AI in practice, but we have collected a few truly mindful implementation approaches by leading companies and they are benefiting from it more than they initially thought. Let’s explore and discover together.

GM applied generative AI in the design phase to reengineer a seatbelt bracket. By consolidating eight individual parts into a single component, the new design was 40% lighter and 20% stronger than the original. Their approach of implementing gen AI got them bundle of benefits including reduced manufacturing complexity, improved durability, and supported fuel efficiency goals.

Whereas, implemented early in the product lifecycle, the generative design process enabled GM to evaluate multiple variations quickly and move toward production with an optimized, manufacturable solution.

2. Volkswagen

Volkswagen used generative AI during the conceptual design stage to create lightweight wheels for its classic Type 2 Bus project. The AI-enabled solution generated numerous design options, directly reducing the workload on engineers by helping them balance strength, aesthetics, and manufacturability. Benefits? The final design achieved an 18% reduction in wheel weight while maintaining performance standards. By introducing generative design at the outset, Volkswagen demonstrated how AI can accelerate innovation, reduce material usage, and contribute to vehicle efficiency and sustainability.

In recent times, we have seen a significant collaboration between Microsoft and Siemens with the launch of a generative AI assistant called Siemens Industrial Copilot. This innovative solution is built with the purpose of boosting productivity in manufacturing by enhancing human–machine collaboration.

For example, Schaeffler AG is already using the assistant for programming robots in industrial automation. Additionally, integration between Microsoft Teams and Siemens’ Teamcenter (product lifecycle management software) is planned, enabling better virtual collaboration among design engineers, frontline workers, and cross-functional teams.

Key Benefits of Leveraging Generative AI in Manufacturing Industry

Generative AI in manufacturing industry is a powerful force enabling fully automated factories and streamlining operations. Its potential for better integration allows it to identify inefficiencies and offer valuable insights across all aspects, from production to the supply chain and client interactions. This technology represents the future of smart manufacturing or industry 4.0 by maintaining high productivity and efficiency levels across operations.

In this section, we will explore the key benefits of generative AI in manufacturing in more depth.

Enhanced Productivity & Efficiency

GenAI in manufacturing processes helps automate repetitive tasks such as inventory management, supply chain operations, order processing, quality inspection, and engaging in human-like conversations with clients/customers. By automatically handling labor-intensive tasks, Gen AI allows manufacturers to utilize their resources for strategic and value-adding activities. Tasks that are powered by generative AI automation are known to be completed in no time, with more consistency and error-free, ushering improved productivity. Moreover, better control and visibility of operations, along with workflow optimization, makes it easy to achieve a higher degree of efficiency.

Smart Saving

Implementing generative AI in manufacturing industry as a cost-reduction strategy is the ideal approach to unlock its potential. Yes, integrating gen AI into operations can drive benefits in terms of operation optimization and cost savings. Manufacturing leaders can leverage this technology’s capabilities to identify bottlenecks and make optimal use of resources before implementing fundamental changes. Combining GenAI technology with digital twins permits engineers to save time and costs by conducting trial-and-error approach.

Costly disruptions occurring due to frequent downtimes can be avoided through Gen AI’s analytical skills. It helps track and address malfunctions in machinery before they escalate, thus reducing costs. Accurate forecasting of fluctuating demand and market trends allows the manufacturing industry to maintain inventory levels accordingly to avoid wastage. Overall, Gen AI offers a tremendously sustainable and profitable manufacturing environment to lead in future competition.

Data-Driven Decision Making

One of the top benefits of generative AI in manufacturing is its ability to enable smarter, data-driven decisions. The combination of Gen AI and data analytics offers benefits beyond traditional data analytics by empowering management hierarchy to uncover hidden patterns and complex relationships within the dataset. Access to accurate real-time insights helps making strategic decisions in various areas of the manufacturing, such as inventory management, supply chain management, quality assurance, production planning, and scheduling.

Improved Product Quality

Generative AI can be trained on vast amounts of product quality and visual inspection data, allowing manufactures to analyze and identify defects in real-time. This capability ensures an immediate jump in the rectifying process, significantly reducing waste.

Its ability to analyze massive datasets empowers on-floor labor to analyze production data and create predictive models of product quality. It enables proactive adjustments to maintain consistency and prevent defects. Furthermore, AI can optimize manufacturing parameters through simulations, identifying ideal settings for high-quality production, thus reducing variability and enhancing product consistency.

Dynamic Workflow Generation in Manufacturing Execution Systems (MES)

Dynamic workflow generation in MES sounds fancy, but really, it’s about not getting stuck when the factory floor doesn’t behave like the PowerPoint. Machines break, orders change, parts go missing. Instead of engineers scrambling with clipboards or managers rewriting schedules, the system reshuffles itself in real time. Generative AI makes it possible to generate new sequences, instructions, and priorities as things shift, keeping workers focused and production flowing. The benefit isn’t magic it’s fewer stoppages, better use of people and machines, and a plant that bends instead of breaks when the unexpected shows up.

Addressing Manufacturing Industry Challenges with the Adoption of Generative AI

All entities associated with manufacturing structures are still struggling with some unremitting challenges. In this section, we will discuss the challenges faced by the manufacturing industry in the implementation of tech-enabled solutions and how generative AI helps to overcome those challenges effortlessly.

Data Management

- Challenge: The manufacturing industry generates a massive amount of data on a daily basis through ongoing execution of operations. Organizing and extracting actionable insights from this untidy data remains one of the critical challenges. It brings complexities and forces engineers to struggle with issues such as data quality and missing values.

- Solution: By leveraging generative AI models like variational autoencoders (VAEs) and generative adversarial networks (GANs), product and process analysts can promptly handle missing values and take actions to rectify noisy or erroneous data in their datasets.

Workforces Skills

- Challenge: Continuous upgrading of technology adoption in manufacturing workflows creates a gap between its execution and the knowledge & skills of the workforce required to implement it proficiently.

- Solution: Generative AI models aid in creating synthetic training data to upskill the manufacturing workforce and generate interactive learning materials like virtual simulations. Also, they automate report generation, providing data-driven insights and recommendations, easing the workload on data analysts, and empowering frontline workers with informed decision-making capabilities.

Data Privacy and Intellectual Property Protection

- Challenge: Safeguarding sensitive data and protecting intellectual property amid increasing AI integration.

- Solution: Generative models can be implemented to create synthetic, anonymized datasets and novel designs, prototypes, and product ideas, reducing the need to share sensitive information and mitigating the risk of theft or unauthorized use.

How to Implement Generative AI in Manufacturing Workflow?

Leveraging the power of generative AI in business operations can seamlessly unlock significant benefits in the forms of productivity, efficiency, and cost savings, but only if it is integrated effectively. For effective incorporation of GenAI within manufacturing workflows, organizations should be more careful and follow a systematic structure.

Here, we have mentioned a step-by-step process for the successful implementation of generative AI for manufacturing:

- Evaluate existing processes and workflow, focus on pain points by conducting a thorough analysis to identify inefficiencies, bottlenecks, and quality issues, and understand how GenAI can proficiently integrate to address them.

- Pre-determine specific use cases by prioritizing manufacturing workflows and tasks that can benefit most from GenAI integration, and clearly outlining the objectives, end result, and key performance indicators (KPIs).

- This step involves gathering and preparing data by identifying relevant data sources, such as production data, sensor readings, and maintenance logs, and ensure data quality, cleanliness, and standardization.

- Select and develop GenAI models by evaluating and choosing the appropriate algorithms and architectures that best fit the identified use cases and collaborate with data scientists and domain experts to train and fine-tune the models.

- Integrate GenAI into manufacturing workflows by seamlessly embedding the trained models into relevant processes, and developing the necessary infrastructure, APIs, and user interfaces.

- Monitor and continuously improve by establishing robust feedback mechanisms to track performance, analyze outcomes, and iterate on the models and integration strategies to maximize benefits.

- Foster a culture of adoption and collaboration by engaging cross-functional teams, promoting understanding and adoption of GenAI, and encouraging collaboration between domain experts and data scientists for continuous innovation.

Why Partner with Rishabh Software for Custom Generative AI Solutions in Manufacturing?

As a leading provider of AI and machine learning development service, Rishabh Software offers solutions built for continual improvement, ensuring that your manufacturing processes evolve alongside technological advancements. We understand the industry challenges and opportunities, which allows us to develop an AI-powered solution that directly addresses your unique business needs.

Our Gen AI development services are designed to accelerate digital transformation by optimizing a wide range of industry processes to improve productivity and reduce operational costs, providing your business with a competitive edge in the market. Our expert team of Gen AI specialists offers comprehensive support and collaboration, ensuring seamless integration and optimal utilization of AI technology in your business processes. Partner with Rishabh Software today and transform your business operation for the future.

Frequently Asked Question

Q: What is the future of GenAI in manufacturing?

A: GenAI’s future impact on manufacturing is enormous. It can smoothen out end-to-end production flows, foresee equipment failures before time, monitor quality by detecting anomalies and supply custom experiences for buyers. With the evolution of GenAI, it will be increasingly integrated into different parts of manufacturing which will have effects like efficiency driving productivity and innovation

With digital twins, manufacturers will be able to simulate entire production lines, test new processes virtually, and predict outcomes before implementation. Integrated with IoT sensors and cloud platforms, GenAI will forecast equipment health, reduce downtime, and ensure sustainable energy use.

Q: What is the potential cost savings associated with Generative AI in manufacturing?

A: As discussed in the use cases, Generative AI reduces costs across various manufacturing operations, including design, supply chain, customer service, and more. In percentage terms, 10% is the minimum cost saving that any manufacturing business can expect.

Q: How does Generative AI influence the adoption of advanced materials in manufacturing?

A: It accelerates material testing and design simulations, enabling manufacturers to explore advanced materials faster and adopt them with reduced risk and cost.