Did you know the global smart manufacturing market is projected to reach USD 479.17 billion by 2029? According Deloitte’s 2025 Manufacturing Industry Outlook, manufacturers are rapidly embracing Industry 4.0 technologies and smart factory initiatives to drive efficiency and innovation.

Therefore, digital transformation in manufacturing industry is the house of opportunities to improve all aspects of manufacturing to capture the true value of Industry 4.0. To innovate and revolutionize how your manufacturing business operates, you need to understand the ins and outs of digital transformation.

Yet, a cloud of questions still surrounds this shift. How can it help your business boost productivity, improve decision-making, and stay competitive? What about the challenges and how do you overcome them to ensure long-term success?

Let us help you with the benefits of digital transformation in the manufacturing industry, potential challenges along with their solutions, key components, use- cases and emerging technologies for a successful digital transformation.

What is Digital Transformation in Manufacturing?

Digital transformation (DX) in manufacturing is the process of integrating advanced digital technologies such as AI, data analytics 5G, IoT, cloud computing into various aspects of the manufacturing industry for real-time insights, end-to-end visibility and scalable solutions. This transformation aims to improve efficiency, productivity, and overall business processes. The key drivers of digital manufacturing transformation are software applications and digitization.

Benefits of Digital Transformation in Manufacturing Industry

Digital transformation in manufacturing revolutionizes how products are created, monitored, and delivered, offering numerous benefits that enhance efficiency, productivity, and overall business performance. Let us walk you through the key advantages of digital transformation in the manufacturing industry and how they pave the way for continued industry growth amid persistent challenges:

Improved Efficiency

Automating various processes, such as inventory management, production scheduling, and quality control, streamlines operations, reduces manual errors and optimizes resource utilization.

Enhanced Product Quality

Advanced data analytics and IoT sensors monitor equipment and production lines in real-time, detecting defects or inefficiencies promptly. This proactive approach ensures higher product quality, reduces the chances of faulty products reaching consumers.

Cost Reduction

Manufacturers can minimize downtime, prevent equipment failures, and optimize maintenance schedules by embracing digital solutions like predictive maintenance, real-time monitoring, and process automation. This not only reduces maintenance costs but also controls costly production interruptions. Additionally, digital technologies also help manufacturers monitor and optimize energy consumption, accurately forecast demand, and enhance quality-control measures to deliver a competitive advantage.

Flexibility and Agility

Digital manufacturing transformation allows manufacturers to be more agile and respond quickly to market changes and consumer demands. The ability to swiftly adjust production levels, switch between product lines, and customize manufacturing processes based on real-time data insights enhances responsiveness to market fluctuations.

Data-Driven Decision Making

The integration of IoT devices and data analytics tools generates a vast amount of valuable data. Manufacturers can leverage this data to gain actionable insights into their operations, enabling data-driven decision-making and fostering a culture of continuous process improvements.

Supply Chain Optimization

Digital transformation in manufacturing enables manufacturers to gain real-time visibility and connectivity into their supply chain. This allows for better decision-making and enables demand-driven planning and forecasting. Manufacturers can thus track raw materials, monitor inventory levels, and collaborate more effectively with suppliers and distributors, ensuring smoother operations and timely deliveries.

Environmental Sustainability

The ideal combination of manufacturing and digital transformation aids companies in adopting environmentally friendly practices. This involves optimizing energy usage, minimizing waste generation, and integrating sustainable production methods. As a result, it promotes a more eco-conscious and sustainable approach to manufacturing processes.

Customer Satisfaction

The benefits of digital transformation prove to be beneficial for the end consumers too. Digital manufacturing transformation helps companies improve product quality, faster delivery times, and customized offerings based on consumer preferences, contributing to higher customer satisfaction and loyalty.

Challenges of Digital Transformation in Manufacturing and Their Solutions

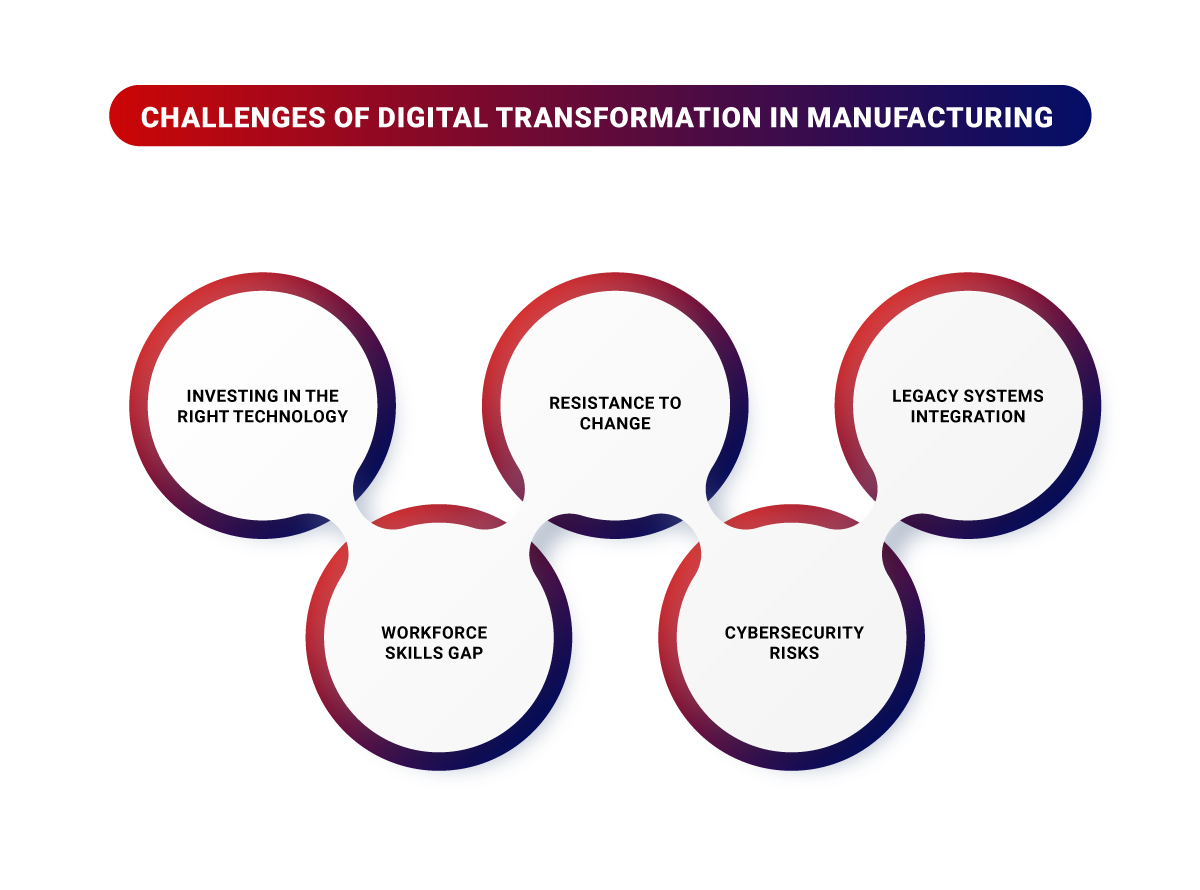

As manufacturers embrace digital manufacturing solutions to streamline operations and boost profits, they encounter hurdles along the way. These challenges act as roadblocks to the seamless implementation of digital transformation of business processes in manufacturing. Let’s understand these challenges along with their solutions.

Investing in the Right Technology

Challenge: Choosing the appropriate technology investments can be a daunting and challenging task for manufacturing companies. For the success of manufacturing companies, investing in the right technology is crucial to get the job done.

Solution: To address this, companies should assess needs, prioritize scalable solutions aligned with business goals, conduct trials, evaluate costs, prioritize flexibility, collaborate with trusted vendors, and encourage ongoing learning. This strategic approach ensures informed decisions for successful digital transformation.

Workforce Skills Gap

Challenge: The shift towards digital technologies such as AI, data analytics and cybersecurity requires a skilled workforce utilizing these new tools and systems.

Solution: Provide comprehensive training programs and upskilling initiatives to empower employees with digital skills. Collaborate with educational institutions or training providers to bridge the skills gap.

Resistance to Change

Challenge: Resistance or reluctance from employees to adapt to new technologies can impede the digital transformation process.

Solution: Foster a culture of change by communicating the benefits of digital transformation to employees. Involve them in the process, address concerns, and encourage feedback to create a sense of ownership and willingness to embrace change.

Cybersecurity Risks

Challenge: The increased connectivity and data sharing in digital transformation expose manufacturing systems to potential cyber threats.

Solution: Implement robust cybersecurity measures such as encryption, firewalls, regular system updates, and employee training on cybersecurity best practices to safeguard against cyber-attacks.

Legacy Systems Integration

Challenge: Many manufacturing facilities still operate with legacy systems that need help integrating modern digital solutions. These present challenges such as data silos, limited scalability and even make systems susceptible to security vulnerabilities or compliance issues.

Solution: Employ middleware or integration platforms that bridge legacy systems and new digital technologies. This enables smoother data flow and interoperability.

Now you know how digital transformation plays a key role in the success of the manufacturing industry. Let us dive deep into understanding several technologies driving digital manufacturing transformation in today’s rapidly evolving digitalized world.

Key Technologies Powering Digital Transformation in Manufacturing Industry

Let’s explore digital transformation examples in manufacturing like AI, IoT, and advanced analytics transforming the traditional manufacturing landscape into an interconnected and data-driven environment.

Internet of Things (IoT)

IoT in manufacturing serves as a network of interconnected tools, sensors, and machinery. These devices collect and transmit data, encouraging a seamless exchange of information across the production floor. Sensors embedded in machines collect valuable information, enabling predictive maintenance, optimizing production processes, and enhancing overall operational efficiency.

IoT technology helps in enhancing results in production processes, personnel management, and asset management.

AI and ML

Artificial Intelligence and Machine Learning technologies revolutionize manufacturing by analyzing vast amounts of data to uncover patterns, make predictions, and optimize operations. These technologies help in predictive maintenance, quality control, demand forecasting, and process optimization, driving efficiency and reducing downtime.

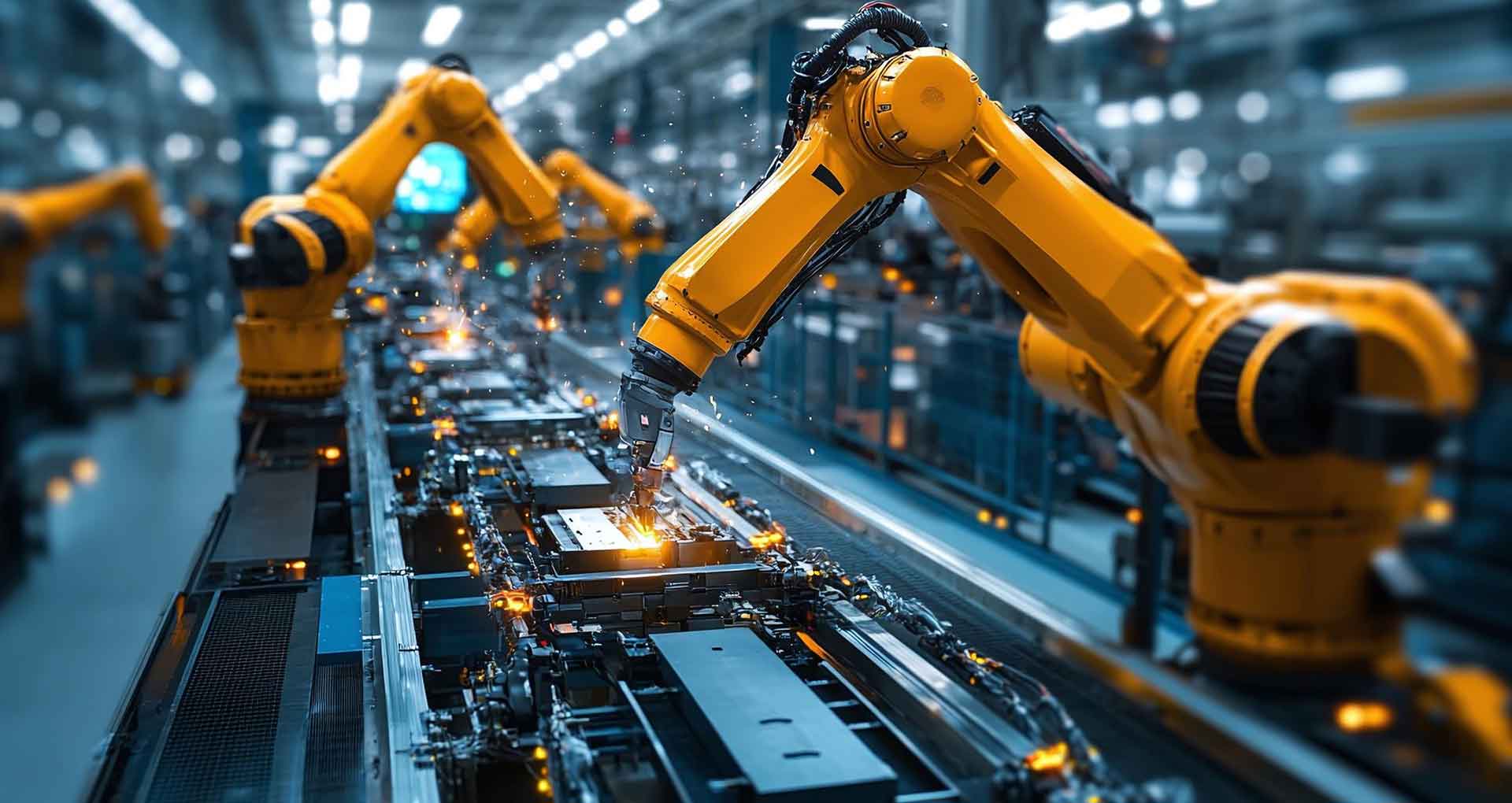

Robotics and Automation

The integration of robotics and automation systems streamlines manufacturing processes. Robots handle repetitive tasks with precision and speed, improving productivity, ensuring consistency in production, and enhancing workplace safety.

Big Data Analytics

Analyzing large volumes of data generated by manufacturing processes yields actionable insights. Big data analytics enables manufacturers to make informed decisions, identify areas for improvement, and optimize various aspects of production, supply chain, and quality control.

Additive Manufacturing (3D Printing)

Additive manufacturing or 3D Printing enables the creation of intricate parts and prototypes using layer-by-layer printing techniques. This technology reduces lead times, allows for customization, and enhances design flexibility in manufacturing. This technology is quick, easy, and affordable for the manufacturing industry.

Key Components of a Successful Digital Transformation in Manufacturing

As a manufacturer, you can improve your operations and get ahead of the competition by embracing Industry 4.0. However, navigating this transformation journey requires a strategic approach and a clear understanding of the crucial components to enable a successful digital manufacturing transformation. Here are the key elements essential for a thriving digital transformation in manufacturing.

Clear Vision and Strategy

Manufacturers need to articulate their goals for digital transformation, outlining how they align with overall business objectives. A robust strategy guides decision-making and resource allocation, ensuring everyone in the organization understands the digital manufacturing transformation’s purpose and direction.

Executive Leadership and Organizational Buy-In

Leadership commitment and support are crucial for digital manufacturing transformation. Leadership teams must champion the digital transformation initiative, advocating for its importance and fostering a culture that embraces change. Securing buy-in across all levels of the organization encourages collaboration, empowers employees, and creates a conducive environment for transformational efforts.

Technology Integration and Infrastructure

Selecting the right technology stack is critical to reap the benefits of digital transformation. Integrating advanced technologies like IoT, AI, cloud computing, and automation requires careful consideration of compatibility, scalability, and security. A robust infrastructure supports seamless connectivity and data flow, enabling efficient operations and decision-making.

Data-Driven Insights and Analytics

Leveraging data as a strategic asset drives informed decision-making during the digital transformation journey. Implementing robust analytics tools and processes allows manufacturers to collect, analyze, and derive actionable insights from data generated across various operations. These insights steer optimization strategies, predictive maintenance, resource allocation, and process improvements.

Agile and Flexible Processes

Embracing agile methodologies and flexible processes facilitates adaptation to changing market dynamics. Manufacturers should prioritize iterative approaches, enabling them to swiftly test, learn, and refine strategies. Process flexibility allows scalability, customization, and quick responses to evolving customer needs.

Talent Development and Upskilling

Investing in workforce development is vital for successful digital manufacturing transformation. Training programs and upskilling initiatives equip employees with the necessary skills to effectively utilize new technologies. Empowered and knowledgeable employees are pivotal in driving and sustaining digital transformation efforts.

Customer-Centric Focus

Placing the customer at the core of transformation efforts is paramount. Understanding customer needs and preferences guides innovation and product development. Digital transformation should enhance customer experience, offer personalized services, and ensure responsiveness to market demands.

Continuous Evaluation and Improvement

Digital transformation is an ongoing journey. Regular evaluation of progress against predefined metrics helps in identifying areas of improvement. Constant refinement of strategies and processes based on feedback and outcomes ensures sustained growth and adaptability.

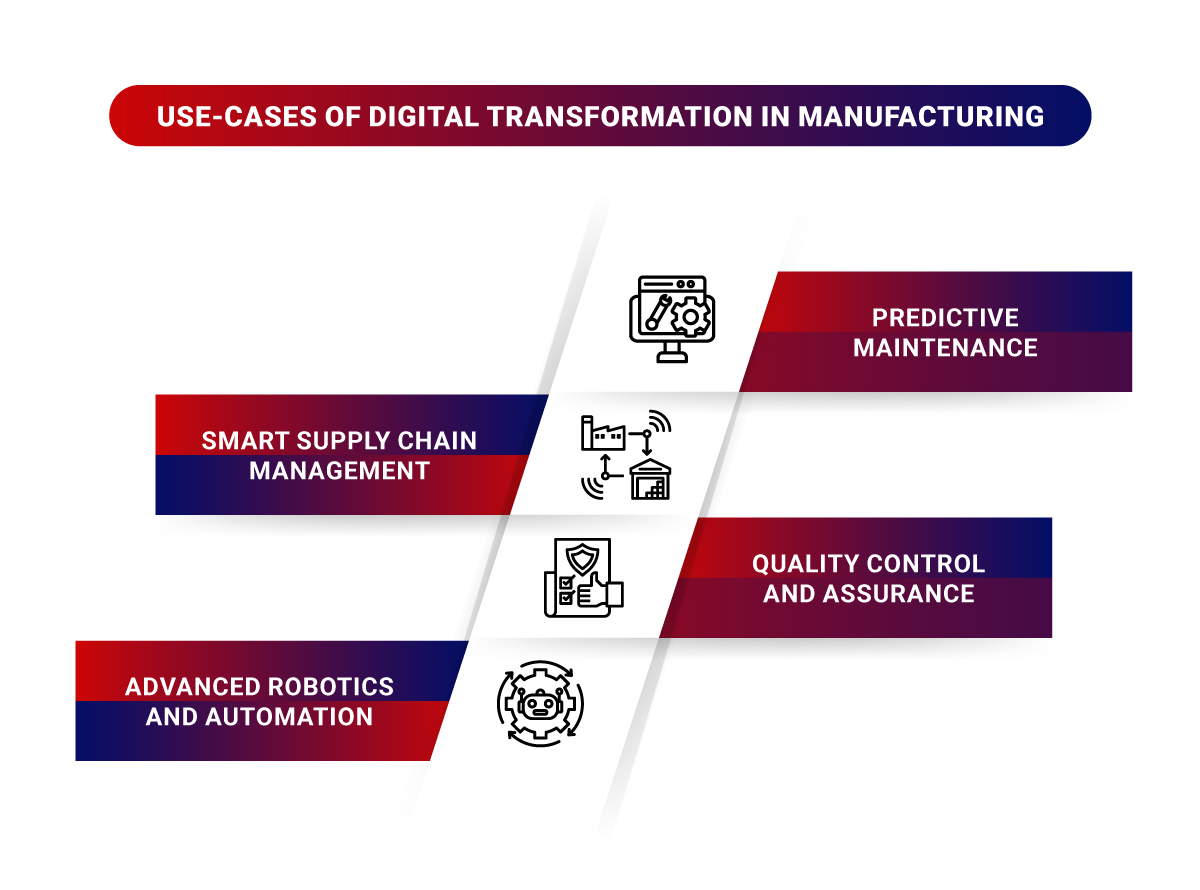

Use-cases of Digital Transformation in Manufacturing Industry

The possibilities for digital transformation in manufacturing are endless. By utilizing the power of advanced technologies, manufacturing companies are reshaping their processes, systems, and strategies. Let’s explore use cases that illustrate how digital transformation fundamentally reshapes and revolutionizes the manufacturing industry.

Predictive Maintenance

Implementing IoT sensors and AI-driven analytics enables predictive maintenance in manufacturing equipment. These sensors monitor machine conditions in real-time, predicting potential breakdowns or maintenance needs before they occur. This proactive approach minimizes downtime, reduces unexpected failures, and optimizes maintenance schedules, saving costs and enhancing productivity.

Smart Supply Chain Management

Digital transformation in SCM involves using technologies like blockchain, IoT, and data analytics. Blockchain technology ensures transparency and security in the supply chain by providing a secure record of transactions. IoT devices track the movement of goods, monitor inventory levels, and analyze data to improve logistics, leading to better inventory management and smoother operations.

Quality Control and Assurance

Integrating AI-powered image recognition and machine learning algorithms enhances quality control processes. Cameras and sensors analyze product defects or anomalies on the production line in real-time, flagging inconsistencies and ensuring high-quality standards. This minimizes waste, reduces rework, and enhances overall product quality.

Advanced Robotics and Automation

The implementation of robotics and automation technologies revolutionizes manufacturing processes. Collaborative robots, or cobots, work alongside human workers, handling repetitive tasks precisely and quickly. Automation streamlines production lines increases efficiency and improves workplace safety by reducing manual labor in hazardous environments.

Future-Proof Your Manufacturing Operations with Rishabh Software

As a digital transformation partner, we are known for offering unrivaled technical expertise and capabilities in the best of the technology stack to drive digital transformation in the manufacturing industry. Our robust services will help you at every step to speed up your operations in sync with changing market dynamics.

Whether you are looking for modernization, optimization, or complete digital transformation, our custom manufacturing software development expertise will help streamline your manufacturing operations by making your production more innovative and efficient. We perform root cause analysis and apply data insights to upgrade the quality while lowering the inspection costs.

Frequently Asked Questions

Q: What are the emerging trends in digital transformation for manufacturing?

A: The landscape of digital transformation in manufacturing is continuously evolving. Here are some emerging trends shaping this domain:

- Edge Computing: The adoption of edge computing is rising, allowing data processing to occur closer to the source (machines and devices) rather than relying solely on centralized cloud servers. This enhances real-time analytics and reduces latency.

- AI and Predictive Analytics: AI-driven predictive analytics is transforming manufacturing by forecasting machine failures, optimizing maintenance schedules, and improving overall equipment effectiveness (OEE).

- Digital Twins: Creating virtual replicas of physical assets using IoT sensors and data enables manufacturers to simulate and predict performance, leading to improved product design, testing, and maintenance.

- Supply Chain Resilience: The focus on building resilient supply chains through digitization and data-driven insights to mitigate disruptions, optimize inventory, and enhance agility in responding to market changes.

- Augmented Reality (AR) and Virtual Reality (VR): AR and VR technologies are being used for training, remote assistance, and enhancing design and production processes, improving efficiency, and reducing errors.

Q: What are the three 3 aspects of digital manufacturing?

A: Digital manufacturing encompasses various aspects, but three primary aspects are listed below:

- Integration of Digital Technologies: Incorporating digital advancements such as IoT, machine learning, robotics, and AI into manufacturing to automate tasks, enhance efficiency, and optimize processes.

- Data-Driven Operations: It requires you to utilize data analytics to gather insights, monitor performance, and make well-informed decisions in operations. This encompasses employing predictive analytics for maintenance, forecasting demand, and optimizing processes.

- Smart Factories and Connectivity: Creating interconnected and intelligent factories where machines, systems, and processes communicate and collaborate seamlessly. This leads to increased agility, reduced downtime, and enhanced productivity.

These aspects collectively empower manufacturers to adapt to changing market demands, optimize operations, and deliver high-quality products efficiently in the digital era of manufacturing.

Q: What are the key digital manufacturing trends shaping 2025?

A: As manufacturers navigate the path toward a connected and resilient future focusing on key areas & trends can key of locked success. Several key trends are going to make the digital manufacturing landscape in 2025 more prominent:

- Next-Generation Automation: Worker shortages, climbing expenses, and the need for greater accuracy push manufacturers to speed up automation. Smart robots and cutting-edge automation are now must-haves, not extras to keep up with rivals, boost production, and meet buyers’ hopes for quicker delivery.

- Scaling Industrial IoT (IIoT): As markets demand instant reactions, manufacturers can’t rely on old reports they need live info. More sensors and linked devices will change production lines into smart, self-checking systems leading to faster better-informed choices.

- Rise of Digital Twins: New ideas come faster, and mistakes cost a lot. Digital twins let manufacturers test products and methods before spending real money. This approach cuts risks, saves time, and helps ideas reach the market faster.

- Cybersecurity as a Key Focus: As business turn into digital ecosystems, the risk landscape grows. Cybersecurity is not just for the IT team, it’s central to business. Leaders know that protecting operational technology (OT) is just as crucial as safeguarding intellectual property or financial systems.

- Going Green with Tech: Rules and customers are pushing for eco-friendly products more than ever. Digital tools will help manufacturers track, improve, and share their environmental impact not just to follow rules but to be at the forefront in a market that cares more and more about the environment.

- Sustainability Through Technology: Digital transformation will serve as a critical enabler of sustainable manufacturing practices, from resource optimization to emissions tracking.