IoT promises far-reaching payoffs in warehouse management, the benefits of which extend across warehouse operations and the entire logistics value chain.

From the use of RFID tags and real-time location systems to smart devices for precise location monitoring, picking, and item tracking, IoT helps tackle difficult warehouse operational and business challenges in innovative ways. The rise of big data analytics, 5G networks, and AI, has further seen the adoption of IoT for warehouse management at an accelerating rate.

An IoT based warehouse management system combines data with automation and analytics, unlocking possibilities. The benefits of IoT technology is numerous and you to can utilize it to optimize efficiency, precision, and profitability. Let’s explore the benefits, common challenges, and IoT applications in warehouse management and ways to overcome them.

What Is the Role of IoT in Revolutionizing Warehouse Management?

Implementing IoT improves inventory efficiency in warehouse and accelerates your response to changing customer demand. It injects tremendous efficiency, accuracy, and visibility. Today, innovative IoT based warehouse management systems allow for remote monitoring and management, significantly reducing reliance on human labor and subsequently cutting down operational costs.

One critical aspect where IoT solutions excel is in mitigating supply chain errors that often lead to substantial financial losses. With this innovative technology integration, warehouses gain real-time visibility into inventory management, providing accurate and timely data. This empowers facility managers to make informed decisions easily and avert costly delays and downtime.

Security is a paramount concern in warehouses, and IoT devices serve as robust safeguards for stocks, equipment, and property. They offer enhanced protection against theft, a particularly critical feature for facilities lacking advanced warehouse management systems.

IoT is a key asset in warehouse management, revolutionizing the monitoring of crucial environmental factors like temperature, pressure, and humidity. By providing real-time alerts and insights, IoT solutions offer proactive measures to maintain ideal storage conditions. This not only safeguards the integrity of stored goods but also extends their shelf life, presenting businesses with a distinct advantage in preventing losses and ensuring product quality.

In essence, IoT integration in warehouse management not only ensures proactive measures to maintain product quality but also acts as a shield against potential financial losses. This transformative technology elevates traditional warehouses into intelligent hubs characterized by heightened efficiency, accuracy, and adaptability.

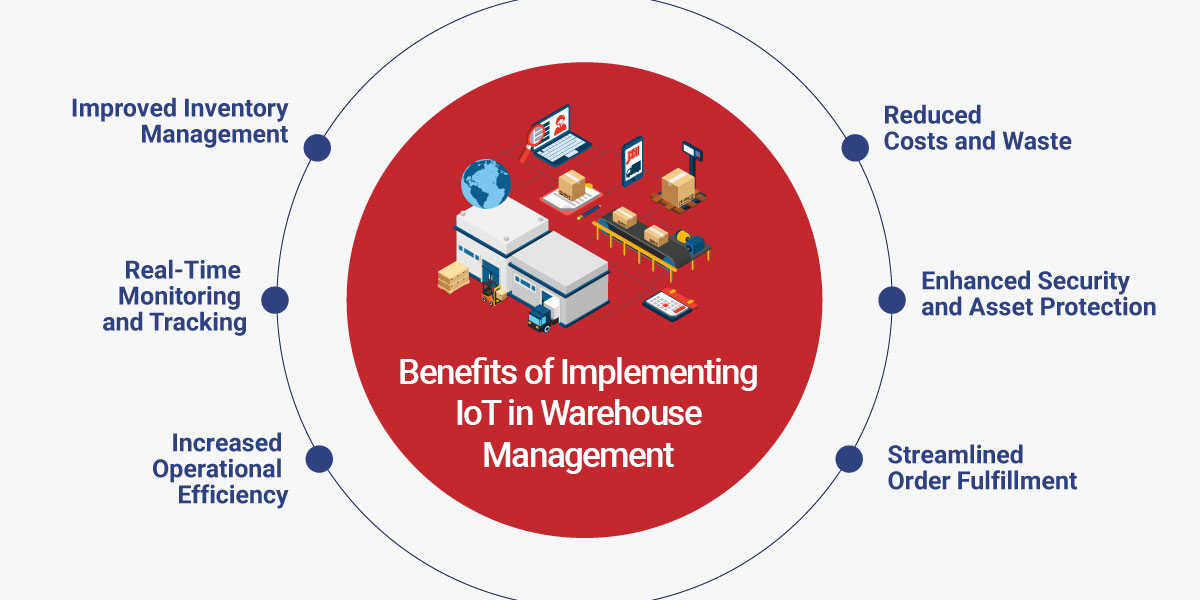

Benefits of IoT in Warehouse Management

IoT-based warehouse management has several benefits and has radically transformed traditional warehouse operations. It increases efficiency and safety while also reducing costs and waste to drive smart warehouse operations. The key benefits of using the Internet of Things in warehouse management include:

Improved Inventory Management:

- IoT enables detailed data analytics for inventory levels, locations, and conditions in real time, eliminating guesswork and manual checks.

- Precise tracking of assets minimizes the time to locate products, optimizing warehouse space.

- Accurate insights into inventory flow inform strategic decisions about stock replenishment and resource allocation.

Here’s an insightful read on how IoT in inventory management is transforming global supply chains.

Real-Time Monitoring and Tracking:

- Beacon technology ensures continuous Bluetooth connectivity for real-time monitoring and tracking of operations.

- Real-time data analysis and intelligent insights optimize processes, reducing expenses on labor.

- Real-time visibility into inventory levels, location, and condition prevent spoilage and overstocking, saving resources and reducing waste.

Increased Operational Efficiency:

- Automation through IoT devices enhances operational efficiency, saving time and costs.

- IoT-enabled systems streamline processes like picking, packing, and shipping, reducing errors and boosting productivity.

- Automated guided vehicles (AGVs) and telematics reduce manual intervention, boosting logistics processes’ speed and accuracy.

Reduced Costs and Waste:

- A predictive maintenance system helps anticipate equipment malfunctions. This enables proactive repairs and reduces equipment defects while minimizing risks and downtime.

- IoT-enabled smart lighting and climate control systems reduce energy consumption.

Enhanced Security and Asset Protection:

- IoT sensors monitor warehouse access, asset movement, and environmental conditions, deterring theft and accidents while ensuring product integrity.

- These sensors gather data and send real-time alerts which enables swift action in case of security breaches or safety hazards, ensuring a secure working environment.

- These will also limit the risk of unforeseen circumstances and provide a secure environment for robust workforce safety. This benefits the organization by providing a secure and safe environment to employees who are involved in every step of the process.

Streamlined Order Fulfillment and Customer Satisfaction:

- Optimized workflows and real-time inventory visibility through sensors and RFID tags enable quicker order processing and fulfillment.

- Reduction in errors ensures customers receive the right products on time, fostering trust and loyalty.

Common Challenges of Implementing IoT in Warehouse Management and Ways to Overcome Them

While IoT offers significant benefits has the potential to transform warehouse management, implementing it presents various challenges. Let’s have a look at each of them and ways to overcome them:

Data Integration and Management

Challenge: Seamless integration of diverse IoT data streams can be complex.

Solution: Employ a comprehensive data management platform that unifies and normalizes data for analysis. Establish clear data governance policies for security and quality control.

Legacy System Integration

Challenge: Many warehouses rely on non-IoT-ready legacy systems, complicating integration.

Solution: Bridge the gap using APIs and middleware solutions for seamless data exchange between IoT devices and existing systems.

Scalability

Challenge: Warehouses need scalable IoT solutions to accommodate growth.

Solution: Opt for cloud-based platforms for flexible resource scaling without extensive on-premises upgrades.

Interoperability

Challenge: Ensuring seamless communication between devices from different vendors can be challenging.

Solution: Prioritize IoT solutions that adhere to open standards and protocols. Conduct thorough testing during implementation to identify and address interoperability issues early.

Change Management

Challenge: Successful IoT adoption requires employee adaptation to new technologies and processes.

Solution: Communicate the benefits of IoT and highlight how implementing it will enhance work efficiency and safety. Also provide training for all staff in IoT technologies, software, and processes along with upskilling or reskilling programs. Start small-scale pilot projects before full-scale roll out.

Cost Considerations

Challenge: High Initial investment in IoT infrastructure. Further, the ongoing maintenance costs for sensor networks, devices, and infrastructure can be significant.

Solution: Conduct a thorough cost-benefit analysis to evaluate potential ROI before implementation. Explore options for phased rollouts or cloud-based solutions to manage costs effectively.

Data Security

Challenge: Protect vast IoT-generated data, especially sensitive inventory and operations information.

Solution: Conduct periodic risk assessments and employee training on cybersecurity best practices. Implement robust cybersecurity measures that include encryption and regular patching.

Right IoT platform and technologies

Challenge: Given the complexities involved and the diversity of IoT solutions, selecting the best fit for your warehouse operations can be overwhelming.

Solution: To select the right IoT platform for your warehouse:

- Prioritize scalability to accommodate future growth

- Ensure seamless integration with existing systems

- Implement robust security measures to protect sensitive data.

- Evaluate the total cost of ownership to balance initial investments with long-term operational costs.

This will help you choose the ideal solution that meets your specific needs and enhances overall efficiency.

We can help you ensure successful IoT implementation in your warehouse right from strategic planning and careful execution to ongoing evaluation for enhanced efficiency, visibility, and control.

IoT devices for Warehouse Management

Various IoT technologies work together to create a smart warehouse. Here are some of the most common:

- Sensors

IoT sensors monitor temperature, humidity, light exposure, and air quality within the warehouse in real time. These ensure optimal storage conditions to preserve product quality and safety.

- RFID Tags and Readers

Tags come in various forms, such as Active, Passive, and Semi-Passive. These are attached to inventory items, pallets, or containers. Interrogators or RFID readers are installed at strategic checkpoints. These enable automated inventory tracking of goods as they move through the warehouse, providing real-time visibility or asset management to prevent loss.

- Beacons

These wireless devices use BLE technology to help in asset tracking by precisely identifying the location of items or warehouse vehicles. Advanced beacons monitor environmental conditions like humidity and temperature for critical inventory.

- AI Cameras

Computer Vision Systems can monitor warehouse processes, identify anomalies or safety hazards, and notify managers of accidents. They can also automate inventory counts and quality control processes.

- Smart Shelves

Smart shelves are equipped with IoT sensors to automatically track stock levels, trigger the automatic reordering process, and eliminate manual counting. Thus, ensuring optimal inventory levels at all times.

- Autonomous Mobile Robots

AMRs can dynamically plan and adjust their routes using sensors and AI. These are designed to work alongside human workers and move materials within a warehouse. They can work 24/7, calculate the shortest routes, restock inventory, integrate with WMS, and mitigate workforce shortage. For instance, Amazon employs over 100,000 robot workers in its smart warehouses

- Inventory Drones

Drones can scan items, record locations, and monitor in real time. They are often used for hard-to-reach areas or night shifts to minimize disruption to operations.

- Edge Computing and Cloud Integration

Edge computing enables real-time data processing and analysis within the warehouse for lightning-fast responses. Cloud integration facilitates fast, accurate data analysis and decision-making for smart warehouses.

- Smart HVAC Systems

These systems leverage AI and predictive analytics to maintain required environmental conditions automatically, optimizing utility costs and energy load. They provide analytics and real-time notifications, leading to significant cost savings and improved sustainability.

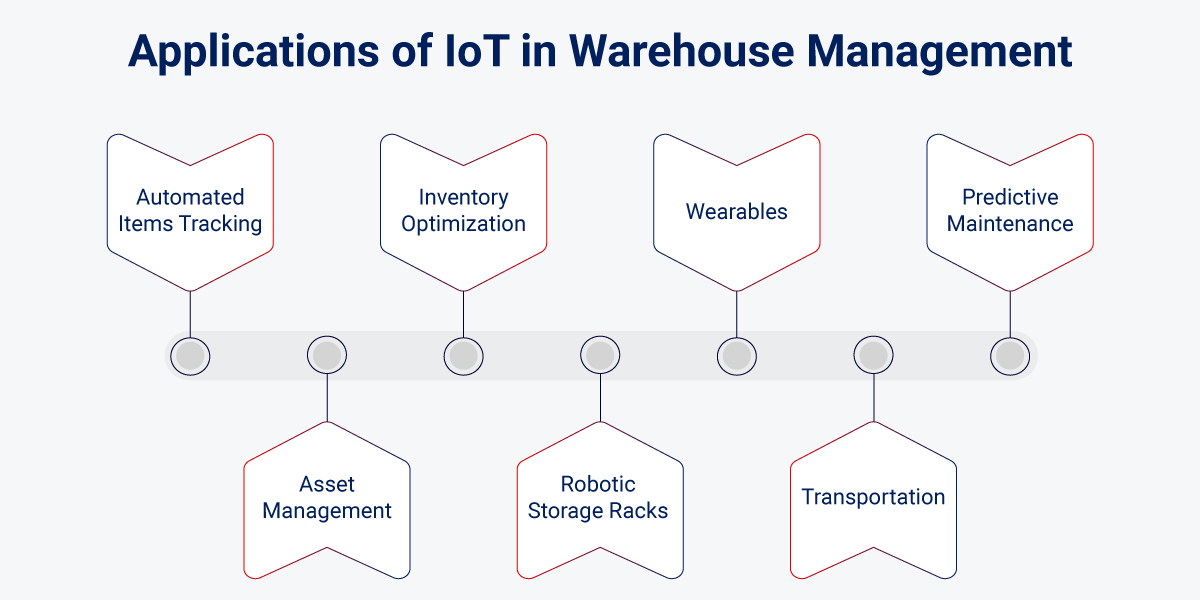

IoT Applications in Warehouse Management

In the contemporary landscape, an increasing multitude of IoT devices are being strategically integrated in various combinations to forge distinctive smart warehouse management systems. However, no one size fits all, therefore it is imperative to conduct a thorough analysis of your business needs. We propose a careful consideration of the most prevalent IoT use cases in this domain.

1. Automated Items Tracking:

Embracing IoT warehouse solutions proves instrumental in efficiently tracking all items entering or exiting a facility. This entails the use of automated detection and scanning codes, coupled with the transmission of this information to warehouse servers.

2. Asset Management:

The deployment of smart sensors on shelves and assets empowers managers to enhance tracking and locate items with precision. Timely notifications about items approaching low stock levels enable managers to take requisite actions promptly.

3. Inventory Optimization:

The capabilities of IoT warehouse systems to comprehensively track all processes and actions facilitate meticulous data gathering and analysis. This, in turn, empowers managers to make well-informed decisions across various facets of stock management and to strategically plan inventory and associated tasks within the supply chain stages.

4. Robotic Storage Racks:

Leveraging Automated Guided Vehicles (AGVs) and specialized robots for tasks such as relocating items and identifying empty shelves accelerates and streamlines warehouse processes. This not only enhances operational efficiency but also contributes to an expedited workflow.

5. Wearables:

Warehouse managers can now monitor their workforce through the distribution of wearable devices. These wearables not only track employee performance, health, and location within the facility but also report incidents such as collisions and falls, thereby significantly enhancing overall operational safety.

6. Transportation:

Telematic devices and GPS feed ensure vehicles adhere to optimal routes, providing real-time updates on the Estimated Time of Arrival (ETA). Additionally, IoT sensors on goods extend beyond mere vehicle-level tracking, offering granular item-level visibility. This detailed information empowers operation managers to adopt a proactive rather than reactive approach in case goods breach predefined thresholds.

7. Predictive Maintenance:

IoT-based predictive maintenance plays a crucial role by constantly collecting data on various parameters such as temperature, vibration, humidity, and operational performance. This approach helps in the early detection of potential issues before they escalate into significant breakdowns.

The data is analyzed using advanced algorithms and machine learning techniques to identify patterns and anomalies that may indicate forthcoming failures. It helps the maintenance teams to address issues before they lead to expensive breakdowns.

This approach not only ensures optimal production but also serves to minimize maintenance costs and optimize maintenance schedules and downtime, thereby bolstering overall operational efficiency.

How Rishabh Software Can Help You Implement an IoT-based Warehouse Management System?

As your trusted IoT app development company, we can help you transform your warehouse into a smart and efficient space that leverages the full potential of IoT:

Industry-specific Expertise:

We leverage our years of development experience and a deep understanding of industry best practices. Our practice-proven team is fully equipped to handle the unique challenges of your specific operation and can efficiently address the complexities of warehouse management and IoT integration. With us, you can be confident of successful implementation of IoT solutions for warehouse management.

IoT Application Development:

We design and deploy a custom IoT-enabled warehouse management solution that aligns with your unique goals and challenges. This includes:

- Strategic sensor placement

- Data integration with existing systems

- Secure cloud infrastructure

- IoT in mobile application development

Experience in Seamless Integration of Analytics and Big Data:

Our practice-proven team helps you unlock the true potential of your IoT data by integrating it with advanced analytics and big data platforms. This enables you to:

- Gain real-time insights into warehouse operations

- Optimize workflows

- Predict maintenance needs

- Identify trends and opportunities

End-to-End Support:

- We’re with you every step of the way, from initial consultation to deployment and ongoing support.

- We provide comprehensive training and knowledge transfer to empower your team.

Frequently Asked Questions

Q: How does IoT in warehouse management work?

A: IoT technology uses internet connectivity to connecting smart devices, sensors, and BLE beacons. These connected devices can track inventory, monitor conditions, and optimize various processes. They collect and transmit data in real-time so warehouse managers can make smart decisions, like knowing exactly what you have, when you need to order more, and how to keep everything fresh and safe.

- RFID tags on boxes are special tags that robots and sensors can read. This helps you stay on top of each box is and where it needs to go.

- Smart shelves: Shelves know how much of each item they hold and even send alerts when stocks are low, like a buzzing reminder to refill. No more lost boxes, wasted space, or frustrated employees.

- Robot couriers: Instead of carrying heavy boxes yourself, robots take orders from the system and zoom around, fetching items and delivering them.

- Sensors keep an eye on everything, checking temperature, humidity, and even if the lights are on. They make sure the warehouse is the perfect place for your precious “honey” (your products!) to be stored.

Q: What are the top technological trends in smart warehousing?

A: Top Tech Trends in smart warehousing include:

- Use of AI-powered robots and autonomous forklifts that are guided by data algorithms.

- Drones are taking flight in smart warehouses for aerial inventory checks and precision deliveries.

- Blockchain’s secure chain of custody ensures complete transparency and traceability across every pallet movement and barcode scan.

- AI forecasts future demand, optimizing stock levels and preventing costly shortages.

- Edge computing is enabling real-time data analysis right within the warehouse, making decisions faster than ever before.

- Implementation of Automated Storage Systems to maximize warehouse space by automating storage and retrieval processes.

- Use of Predictive Analytics for forecasting demand, maintenance requirements, and sales trends.

- 3D Bin Packing helps optimize smart spaces by intelligently packing items in a three-dimensional manner.

- Automated Document Insertion is streamlining document handling processes for efficiency and accuracy.

Q: Can you list real-world examples of IoT in warehouse management?

A: Here are 3 successful examples of how IoT is transforming warehouse management:

- Amazon uses smart bots to automate material handling, accelerate order processing, and optimize operations.

- DHL uses smart sensors in their operations for various purposes such as real-time tracking, inventory management, temperature controlling and process optimization.

- Walmart employs self-driving forklifts to move pallets safely and efficiently without needing any manual maneuvering.

30 Min

30 Min