Explore how Rishabh Software helped digitize the beer-line cleaning operations with a dedicated IoT Mobile App to free up staff & optimize their work schedules while enabling cost reduction for the draught beer operations.

Project Overview

An Ireland-based provider of automated beer-line cleaning equipment and beer dispense solutions was in pursuit of developing a compatible IoT-based mobile & web solution to streamline the draught line cleaning process for their customers. This would help improve staff productivity & increase sales. Their existing clientele includes brewers, stadium operators, pub companies, and other businesses from the hospitality industry across Europe.

Learn how Rishabh as their technology partner helped develop from scratch the IoT Mobile App for draught quality management to improve the effectiveness & efficiency of the line cleaning process.

Challenges

- Limited knowledge about the firmware integration with the portable cleaning device

- Lack of efficient data monitoring to verify clean beer lines

- No accurate tracking of cleaning schedule and service activities

- Difficulty in managing cleaning parameters data for user accounts, outlets, and more

- Inaccurate synchronization of the recorded data from the cleaning process

Solution

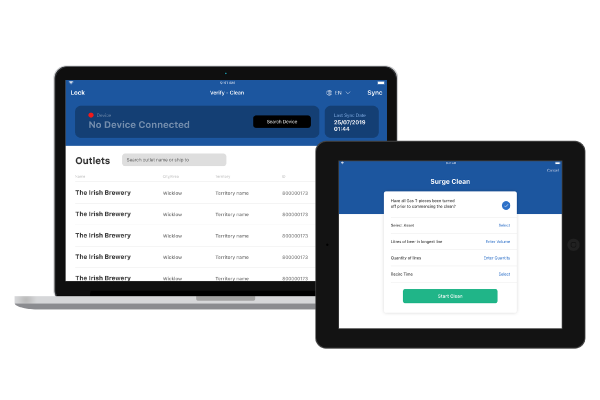

Our team followed a phase-wise implementation approach to ease out the line-cleaning operations. It was divided into two phases: 1) building a new mobile solution for Android & iOS devices and 2) integration with flow sensor hardware to capture data points

Phase-1: Assessment (AS-IS analysis) and App Development

Based on a comprehensive requirement gathering & review of the current ecosystem of the business, our team developed a Xamarin app to target both the OS devices.

It helped offer:

- Authorized access through pin-based authentication

- Encryption of sensitive information such as passwords, tokens & more before being stored in the database

- Enabled Bluetooth-based data transfer communication between the mobile app and cleaning unit/machine

Phase-2: Integration with Flow Sensor Hardware

We integrated the Xamarin app to communicate with the software of Nordic Semi Device – nRF52840 with Bluetooth Low Energy (BLE) technology 5.2 SoC (System-on-Chip).

The app would send the instructions as highlighted below to the cleaning monitoring device;

- Start Clean Command to make the hardware to start the line-cleaning

- The hardware would start work on the cleaning process by assessing: ProcessType, Number of cleaning steps, Flowrate average, temperature average, Flowmeter Calibration

- Further, the device would map the initial configuration parameters related to each step involved in the cleaning process, including Liquid Volume measurement, input next step, max conductivity, min conductivity, max liquid timeout, step number, step type, etc.

- Read step’s status: Before completion, the hardware device would provide information on the current step status, error code, if there’s any

- Cancel the earlier assigned clean command

- Get step measurements and report errors measurements

Benefits

- IoT application helped monitor and validate 12,000+ beer-line cleaning visits/month efficiently

- Real-time data monitoring to standardize the beer-line cleaning process leads to delivering excellent beer quality

- Improved cleaning solutions for the existing and new clientele

- Low cost of ownership enabled higher business profitability

Customer Profile

Ireland-based leading provider of automated beer-line cleaning, monitoring, and dispensing solutions.

Technologies

Angular, PostgreSQL, Kendo UI, .NET Core, Flutter, Bluetooth 5.0