Today’s oil and gas industry stands out as heavily reliant on technology & substantial investments. Even the slightest mistakes, malfunctions, or inaccuracies could result in immense financial losses that could amount to billions of dollars. However, introducing IoT (Internet of Things) technology to this industry has emerged as the solution to numerous challenges.

Custom IoT solutions help significantly reduce expensive downtime, improve operational efficiency and safety, and optimize performance across all production stages. As a result, they have played a pivotal role in transforming and modernizing this industry.

Did You Know?

- The global market for IoT in the oil and gas industry is expected to hit USD 54.48 billion in 2029 from 10.59 billion in 2021[1], growing at a CAGR of 23% during the forecast period.

Despite the present challenges of IoT in the oil and gas industry, the rapid progress has enabled the sector to surpass other [2]capital-intensive industries in terms of innovation and efficiency.

This blog explores the role of the Internet of Things in the oil and gas industry, highlighting how companies can leverage smart technologies to their advantage.

What Is the Role of IoT In Oil and Gas Industry?

IoT for the oil and gas industry involves implementing interconnected devices, sensors, and systems. It enables data collection, communication, and analysis across sectorial operations. It would include integrating digital technologies with physical assets and infrastructure that help enhance operational efficiency, safety, and decision-making.

Forward-thinking oil and gas organizations are tapping into “brownfield” IoT infrastructure, making the most of existing assets, and exploring groundbreaking business models. With IoT, companies can gather unprecedented amounts of data from every corner of their operations – from equipment, facilities, and other assets, thus enabling remote monitoring & control. This data would include parameters such as temperature, pressure, flow rates, equipment performance & environmental conditions.

IoT devices & sensors are deployed throughout the production, transportation, and distribution processes to collect and transmit this data. This collected data is further analyzed using advanced analytics & machine learning algorithms to derive insights and make informed decisions. This information can be used for predictive maintenance, detecting anomalies, optimizing production processes, improving safety protocols, and minimizing downtime.

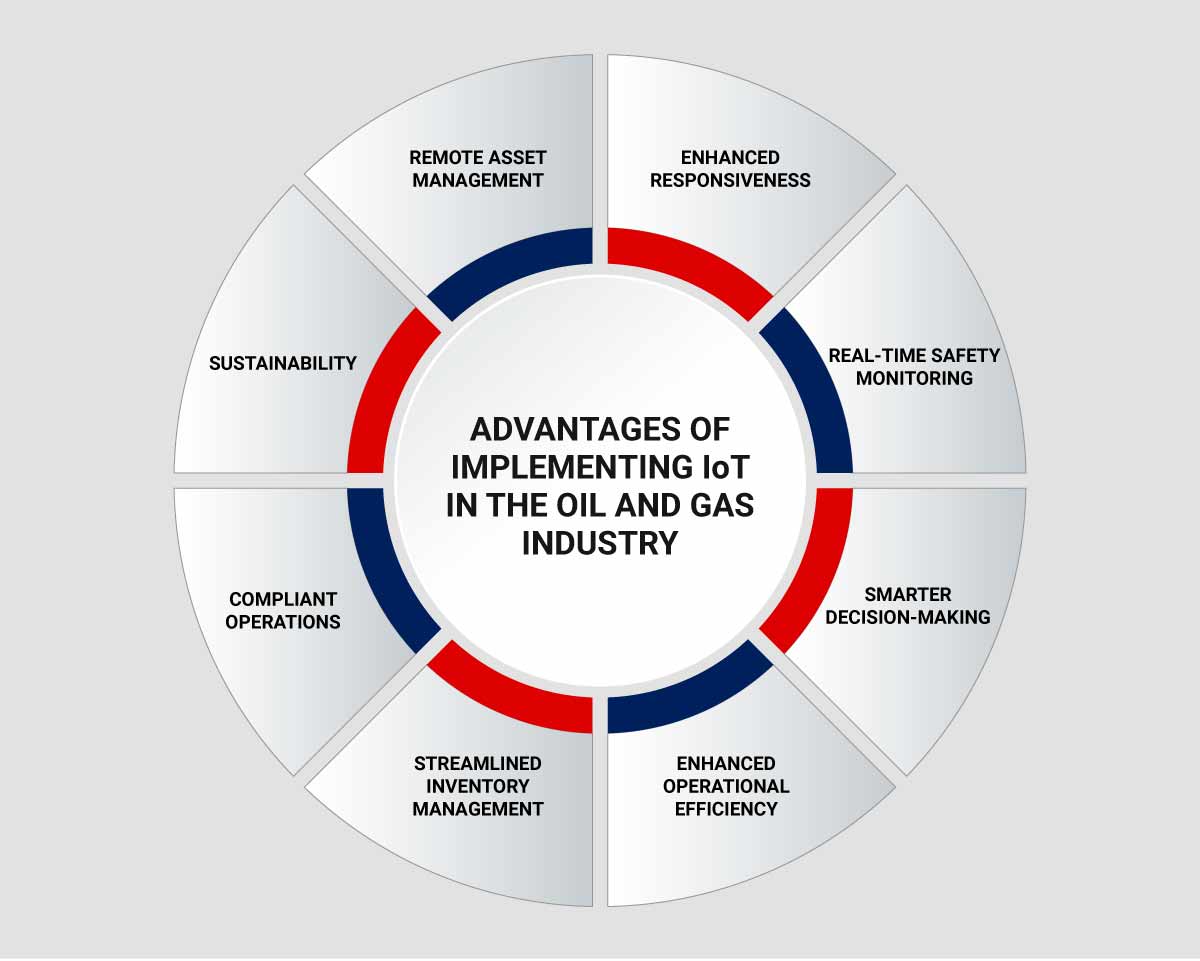

Benefits of IoT in Oil & Gas Industry

IoT enables real-time visibility into every aspect of oil and gas operations. It empowers companies to predict and prevent equipment failures and proactively manage safety hazards. Here’s how it is transforming the way oil and gas companies operate:

- Remote Asset Management: Oil and gas companies constantly want insights into their assets and equipment because profitability in the oil and gas industry is closely linked with asset uptime. By enabling remote real-time asset management across the complex network of fixed and moving equipment, IoT technology helps improve product yield, energy efficiency, and unit/facility downtime.

- Enhanced Responsiveness: Real-time monitoring and data analysis minimize response time, which helps identify potential issues before they blow out of proportion. Thus, you can proactively maintain your assets, avoid costly unplanned downtime, and make production more efficient.

- Real-time Safety Monitoring: Oil and Gas companies constantly face the risk of accidents. Real-time safety monitoring with instant alerts helps detect leaks or other anomalies in real-time and prevent fatal accidents. Thus, by detecting potential risks in advance, you can create a safer work environment for your employees and reduce downtime as well.

- Smarter Decision-Making: Whether you want to optimize processes, cut costs strategically, or identify new business opportunities, IoT-generated insights enable better decision-making with real-time insights.

- Enhanced Efficiency: By leveraging advanced data analytics and machine learning, you can uncover trends and patterns to optimize production efficiency.

- Streamlined Inventory Management: Enables automating inventory tracking and optimization to ensure optimal levels at all times while minimizing the risk of shortages or the cost of overstocking.

- Sustainability: IoT technologies are crucial in reducing the oil and gas industry’s carbon footprint by detecting leaks, improving energy efficiency, and ensuring environmental compliance.

- Compliant Operations: Connected devices provide comprehensive data on facility operations, making it easier for oil and gas companies to comply with industry standards and applicable regulations.

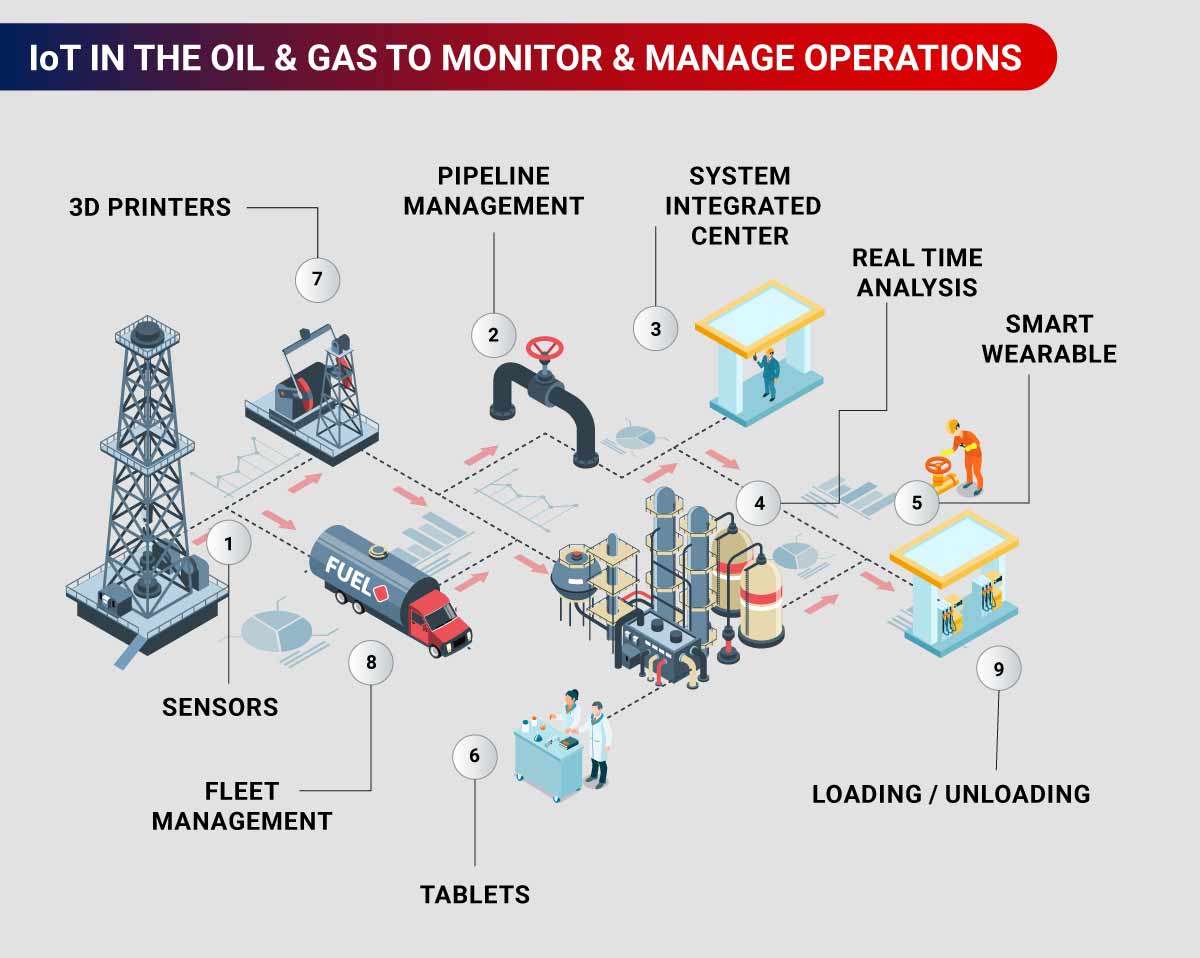

Internet of Things Architecture for the Oil and Gas Industry

By leveraging IoT technologies, organizations can connect various devices, sensors, and equipment throughout their operations. It would allow them to gather real-time data while enabling remote monitoring &control to optimize their processes. This comprehensive & integrated IoT architecture highlights the key components and considerations in designing an IoT architecture tailored to the unique requirements of the oil and gas industry.

- Sensors: For Oil & Gas industry, tracking the live location of vehicles has always been a challenge. Though, advancements in sensor technology enabled by IoT help play a crucial role in gathering data such as flow rate, temperature & pressure. The said sensors are connected to wireless networks via gateways at the site. And once connected, field engineers can access this data via smartphones & tablets for analysis.

- Pipeline Management: It is yet another critical aspect of the industry. Industry reports estimate losses of about $10 billion due to fuel leakage. Therefore, the need for optimized pipeline routes has become apparent. A dedicated solution would help reduce downtime & enable scheduled maintenance. Further, sensors monitor factors like temperature, flow & pressure while providing valuable insights for end-to-end pipeline inspections.

- System Integrated Centers: They have proved essential for integrating IoT platforms across core business processes. They receive data from various devices and can send alerts for immediate action after quick analysis. However, the challenge lies in technical integration and deep understanding of the data. And hence different organizations adopt different control centers capable of capturing crucial data related to time, temperature & pressure.

- Real-time analysis: It is considered crucial when dealing with complex data. Therefore, predictive analysis enables the accurate time tracking of data while alerting the engineers of any changes in equipment behavior. And based on the timely alerts, the engineers can make necessary adjustments to prevent failures or disruptions.

- Smart Device Utilization: Oil & Gas workers utilize IoT tools, such as tablets & smart wearables, to access & monitor systems remotely. They offer real-time information & facilitate data analysis across any location while improving operational efficiency.

- 3D Printing: The adoption of 3D printing technology for the oil and gas industry has been slow. Yet it is still proving to be a valuable solution since reverse engineering plays a significant role in measuring the shape and size of every tool.

- Asset Management & Utilization: The loading & unloading of trucks is equally critical for efficient asset utilization for the transportation & logistics business. IoT solutions enable real-time monitoring of loading and unloading processes while ensuring compliance with regulations toward maximizing profit potential.

- Fleet Management: Interestingly, fleet management has dramatically benefited from IoT technology. Installing off-road sensors in vehicles helps track real-time location & health. Intelligent fleet systems help increase efficiency & reduce traffic incidents. And, while the sensors monitor data from multiple locations, they enable risk reduction. Explore how ELD Fleet Management Mobile App Development with IoT-enabled sensors allows live tracking of cargo & commercial drivers.

IoT Applications in Oil and Gas Industry

The impact of IoT in oil and gas market, whether upstream, midstream, or downstream, is to make production more efficient through predictive equipment maintenance and real-time asset tracking. Oil field production uses a lot of rotating equipment, such as pumps and compressors, both at the surface and inside the oil well. The traditional way to maintain this equipment was run-to-failure or preventive maintenance, which is very inefficient. IoT data can feed analytics and machine learning to achieve predictive maintenance and its multi-fold benefits.

Here’s how IoT is revolutionizing different operational areas while creating a more sustainable and interconnected oil and gas industry:

Data acquisition and analysis:

- IoT-enabled sensors are placed at strategic locations along the pipeline to collect real-time vibration patterns and seismic data and detect any anomaly that may indicate a problem, thus, accelerating exploration and providing insights into subsurface structures.

- Advanced analytics combined with IoT data create precise reservoir models, optimizing decision-making in drilling and extraction.

Drilling optimization:

- Integrating IoT devices optimizes drilling operations, reducing costs and risks.

- Real-time monitoring of drilling parameters facilitates instant adjustments, thus driving efficiency.

- Predictive maintenance helps catch equipment problems ahead of time which helps minimize downtime and extend equipment lifespan.

Production tracking and optimization:

- IoT sensors continuously analyze well-performance to identify optimization opportunities, resulting in increased efficiency.

- Automated control of production processes enables real-time parameter adjustments, which helps maximize output and reduce operating costs.

Pipeline monitoring and maintenance:

- Sensors monitor pipeline conditions, enabling real-time leak detection and prevention.

- Early warning systems provide immediate alerts, minimizing environmental impact.

- Corrosion monitoring and predictive maintenance ensure pipeline integrity and minimize downtime.

One of the important IoT Use Cases in the Oil and Gas Industry would include the application of pipeline monitoring and leak detection by Chevron. They are the second largest oil company in the U.S. that employs IoT technology for pipeline monitoring and leak detection. They embedded IoT sensors along their pipeline infrastructure to monitor its pressure, flow rate, and temperature continuously. As a result, they could quickly identify anomalies or potential leaks by analyzing this data in real-time. The mechanism allows them to take immediate action to mitigate risks, prevent damage, and ensure the safety of their pipelines.

Energy consumption optimization:

- IoT optimizes energy usage by monitoring and controlling pumping systems.

- Integration with renewable energy sources reduces reliance on fossil fuels.

- Data analytics enable energy management, reducing waste and environmental footprint.

Refining and processing:

- Real-time monitoring of process variables improves efficiency and productivity.

- Advanced analytics facilitate data-driven decision-making for optimization.

- Equipment monitoring and predictive maintenance reduce downtime and extend equipment lifespan.

- Safety and environmental monitoring ensure compliance and mitigate risks.

Logistics and distribution:

- Real-time location tracking optimizes routing and asset utilization.

- IoT-enabled systems improve inventory management and enhance safety and security.

- Smart metering and billing provide accurate data for efficient billing processes and enhanced customer experience.

How can IoT Help Address Challenges Faced by Oil and Gas Industry?

Listed below are some of the critical challenges faced by the Oil & Gas industry:

- Equipment monitoring and maintenance to monitor the health and performance of critical equipment such as pumps, valves, compressors, and turbines. Oil and gas operations often involve remote locations, making it difficult to monitor and manage assets effectively.

- Monitoring & analyzing environmental conditions, such as detecting gas leaks, monitoring air quality, and measuring noise levels.

- Managing complex supply chains with numerous stakeholders.

- Better inventory management to capture the movement of assets, materials, and products while improving logistics planning & reduces delays

Listed are some of the ways how IoT can help:

- Remote Monitoring & Control: By deploying IoT devices in remote locations, organizations can monitor equipment performance in line with environmental conditions and by mapping safety parameters. It enables real-time data collection and analysis while allowing operators to identify potential issues, take preventive actions & further optimize operations.

- Predictive Maintenance: With the help of IoT sensors, organizations can continuously monitor equipment parameters such as temperature, pressure, and vibration. It enables the application of predictive maintenance algorithms that analyze data to identify patterns & predict equipment failures before they ultimately, this help with proactive maintenance, reducing downtime, and extending the lifespan of critical assets. Read this blog to learn the use of IoT in predictive maintenance and how it helps companies across industries to cut unplanned downtime and thrive in the Industry 4.0 era.

- Safety & Emergency Response: It is one of the most crucial applications of IoT – the said devices help monitor worker safety, detect hazardous conditions, and provide real-time alerts in case of emergencies.

- Environmental Monitoring & Managing Compliance: By monitoring environmental parameters such as air quality, water quality, and emissions, IoT sensors enable operators to ensure compliance with environmental regulations, detect leaks or spills, and take necessary corrective actions.

How Rishabh Can Help Oil & Gas Businesses Go Smart with IoT

As an experienced IoT application development company, we understand the varied nuances of IoT technology to help organizations from various industries, including oil and gas companies. And drawing on our experience in IoT and data analytics, we help you build custom IoT solutions that drive operational efficiency, cost savings, and sustainable growth.

Here’s our proven approach to leverage the power of IoT and help transform these challenges into opportunities for growth and efficiency.

Tackling Upstream Challenges with Custom IoT Solutions

With our IoT application development services, we can help you develop custom applications that enable real-time monitoring of drilling and extraction processes. Our team can also help you with the following:

- Integrating IoT sensors and devices for collecting and transmitting data from remote locations.

- Developing a secure and scalable cloud infrastructure for storing and processing the collected data.

- Applying advanced analytics and machine learning algorithms to analyze the extracted data for planning predictive maintenance.

Streamlining Midstream Operations with IoT Integration and Implementation

We have extensive experience in working with gateways, data analytics tools like AWS IoT Analytics, AWS IoT SiteWise, and Apache iota, as well as big data tools such as Apache Hadoop, Apache Spark, Apache Storm, Cassandra, and MongoDB. It enables us to offer you seamless connectivity, swift data processing, and operational excellence in the midstream sector by assisting you with the following:

- Selecting the most suitable devices for your midstream operations. We also ensure that they are correctly configured and connected to the IoT network.

- Integrating smart devices into your midstream operations to simplify processes, optimize transportation, and ensure the safe delivery of your products while meeting international emission regulations.

- Enabling real-time monitoring, data collection, and analysis to help you drive informed decisions for optimized midstream processes.

Improving Downstream Efficiency with IoT Consulting

Our IoT consulting services can help you identify areas within downstream operations where IoT technology can be leveraged for predictive maintenance, supply chain optimization, quality control, and safety monitoring.

Key Takeaways

Oil and gas companies integrating IoT solutions are not just dipping their toes in the water—they’re predicted to recover their costs within three years[3] of implementing these advanced technologies.

With IoT in their arsenal, oil and gas companies can gain the superpower to scale up or cut back on resources based on their operational integrity and bottom line. But that’s not all – IoT allows companies from this industry to implement best practices like never before. How? By significantly reducing manual labor and granting access to real-time global insights and seamless cross-departmental collaboration.

Imagine the impact of having a streamlined, super-efficient operation where manual tasks take a backseat and intelligent technology takes the wheel. The ripple effect is profound – minimal downtime, significant savings, a surge in revenue, satisfied customers, and your business running at peak efficiency!

FAQs

Q: Can you list the top IoT Solutions Impacting the Oil & Gas Industry?

A: Here are some of the most popular and preferred IoT solutions

for oil and gas industry:

- SCADACore – Industrial IoT Monitoring: With multi-line trending, alarm callouts, and round-the-clock support, the SCADA architecture helps oil and gas companies improve asset utilization and reduce downtime.

- Codovia – Mobile Applications: Codovia’s mobile applications enable remote asset monitoring, fuel management, and operational insights. With GPS tracking and real-time assistance, it constantly tracks operations and customer relationships to drive better business outcomes.

- ThingsConnect – Smart Devices: ThingsConnect provides connected hardware solutions and an IoT platform for data processing and analysis. By leveraging wireless technology, oil and gas companies can remotely monitor their facilities, boost efficiency, and optimize asset management.

- FourC – Machine-to-Machine (M2M) Communication: This distributed cloud platform enables swift and seamless energy data collection, exchange, and analysis. It’s built to reduce downtime, improve safety, and enhance efficiency.

Q: What is the step-wise approach to adopt IoT in Oil and Gas Industry?

A: You can follow these steps to create a more connected and efficient oil and gas infrastructure:

- Identify your operational challenges and key business processes where IoT can make a difference. Whether it’s remote monitoring, asset management, inventory management, or predictive maintenance – define specific areas where you think IoT can add value.

- What is it that you want to achieve with IoT implementation? Improved efficiency, reduced downtime, or enhanced safety? Set targets that align with your business objectives.

- Look for a reliable and experienced IoT solutions provider with prior experience in developing and implementing IoT solutions successfully.

- Kickstart a pilot project to test the waters. Choose a specific area or equipment to implement IoT solutions and evaluate the results. Doing this will help you minimize your risks and maximize your returns.

- When the positive impact of IoT is visible, you can expand its implementation across your business operations. Slowly, you can integrate IoT into your critical processes and equipment while staying on top of outcomes.

- Provide your employees with the required training and support to adopt and use IoT solutions optimally. Help them understand the benefits and make the most of the technology to be more productive and efficient.

- Track the performance of your IoT systems consistently and upgrade as and when needed. Also, refine your IoT strategy to maximize its impact as you continue to adapt to evolving business needs.

- Stay on top of the latest advancements in IoT technology and consult your technology partner to explore new possibilities to enhance operational efficiency further.

Q: What are the Key Segments Covered by IoT Powered Oil and Gas Business Solutions?

A: IoT-powered oil and gas business solutions can efficiently cover upstream, midstream, and downstream operations, to help you achieve & improve performance across stages. Here’s how:

- Upstream Operations: Implementing the Internet of Things in upstream oil and gas can help with more efficient, better management of drilling and extraction processes, reduce unproductive time, and improve overall operational efficiency in the upstream sector.

- Midstream Operations: IoT has disrupted midstream operations by enabling remote real-time monitoring of assets. With 360-degree visibility, oil and gas companies can easily optimize their fleet management approach, pipeline maintenance schedules, and supply chain operations.

- Downstream Operations: The implementation of IoT in downstream oil and gas helps streamline the processing and distribution of oil and gas supplies, boost operational effectiveness, reduce costs, and enhance customer satisfaction with safe and swift deliveries.

Footnotes:

1. https://www.maximizemarketresearch.com/market-report/global-internet-things-iot-oil-gas-market/10486/

2. https://www.statista.com/statistics/1183457/iot-connected-devices-worldwide/

3. https://www.gartner.com/en/information-technology/insights/internet-of-things