The supply chain and logistics networks worldwide are undergoing unprecedented challenges and changes. They are increasingly turning to Industry 4.0 technology for solutions, with the Internet of Things (IoT) tech as the critical component.

Today, IoT is transforming supply chain management (SCM). Forward-looking organizations leverage IoT devices to transform complex supply chains into fully connected networks. For supply chain management verticals, tracking & monitoring are some of the main objectives of IoT deployment. The technology allows warehouse and fleet managers to keep track of their cargo and inventory.

This article will discuss IoT’s importance for supply chain management & logistics, its benefits, use cases, and more.

For logistics & SCM operations, tracking is one of its crucial applications. Usually, the entire supply chain suffers from cascading effects when something goes wrong at some stage. So, IoT helps prevent bottlenecks & ensure the smooth functioning of the supply chain from manufacturing & warehousing to transport & delivery. However, there’s more to the Internet of Things than its asset management potential.

IoT combines the power of analytics, cloud, mobile computing & internet networks to change how companies manage their supply chain and logistics. IoT devices would include sensors, trackers & more to connect computer systems through wi-fi networks, GPS, and other technologies to track products & deliveries. They collect real-time data, which is then stored, processed & analyzed in the cloud. IoT saves time & effort by automating several processes or activities throughout the supply chain. It eliminates human errors & prevents significant incidents before they happen.

Did you know?

According to Allied Market Research, the global digital supply chain market is projected to register a CAGR of 13.2% and reach $13,679 million by 2030. The factors driving growth include:

- Rise in the use of digital technology,

- Increased demand for fast & reliable order execution, and

- Surge in need for cloud-based supply chain management systems

Also, 6 in 10 businesses plan to invest in digital technologies, including IoT, in 2023, according to a KPMG report. The investment will be mainly to:

- Enhance visibility with better supply chain analytics,

- Uplift the maturity of supply chain planning,

- Automate operational & warehouse tasks.

Role of IoT in Supply Chain Management & Logistics

You can find applications of the Internet of Things in every stage of supply chain management. Here are a few examples:

Real-time Tracking of the Location of Goods & Shipments: Supply chain managers can attach interconnected IoT devices to products or storage containers.

- The GPS satellites pick up location information transmitted by IoT devices. It makes tracking the movement of goods & shipments easier.

- Additionally, they get notifications if the shipment starts moving in the wrong direction or has halted at an unauthorized place.

- And timely intervention by managers helps avoid delays or loss of goods.

Monitoring Storage Conditions: Environmental factors are one of IoT’s most important applications in the supply chain.

- It would include temperature, light intensity, pressure, humidity, exposure to the atmosphere, and much more.

- Supply Chain managers help monitor & maintain the required environmental thresholds within the shipment and other storage facilities like warehouses. It helps reduce or even eliminate spoilage of perishable goods.

Better Estimation of Goods’ Arrival Time: IoT helps in the efficient processing of materials & reduces their handling times.

- It allows supply chain managers to estimate their arrival time better. They can do this by tracking the speed of movement & the traffic congestion hampering the shipment’s movement.

Improved Contingency Planning & Risk Mitigation: Supply chain managers can get to the cause of shipment delays.

- It is enabled by analyzing the data of previous shipments gathered by IoT devices. And this would include data concerning weather, traffic, possible accidents & more.

- Further, they can mitigate risks by creating flexible plans with alternate routes. So when they receive real-time alerts suggesting delay due to traffic, they can direct the shipment to an already designed alternate route.

Locating Goods in Storage: Warehousing facilities have immensely benefitted from the application of IoT technology. IoT makes the management of goods & finding a specific product in a large warehouse easier. It streamlines & automates workflows while enhancing productivity & employee safety.

- When combined with Artificial Intelligence (AI), IoT can automate complete warehouse operations, requiring little or no human supervision.

- IoT devices like Bluetooth Low Energy (BLE) beacons & Radio-Frequency Identification (RFID) sensors help tag goods. It enables tracking of goods’ location on a particular aisle or their movement within the facility.

Triggering Post-arrival Administrative Tasks: IoT’s real-time tracking enables supply chain managers to initiate administrative tasks like onward shipping requests, quality inspections, or payments.

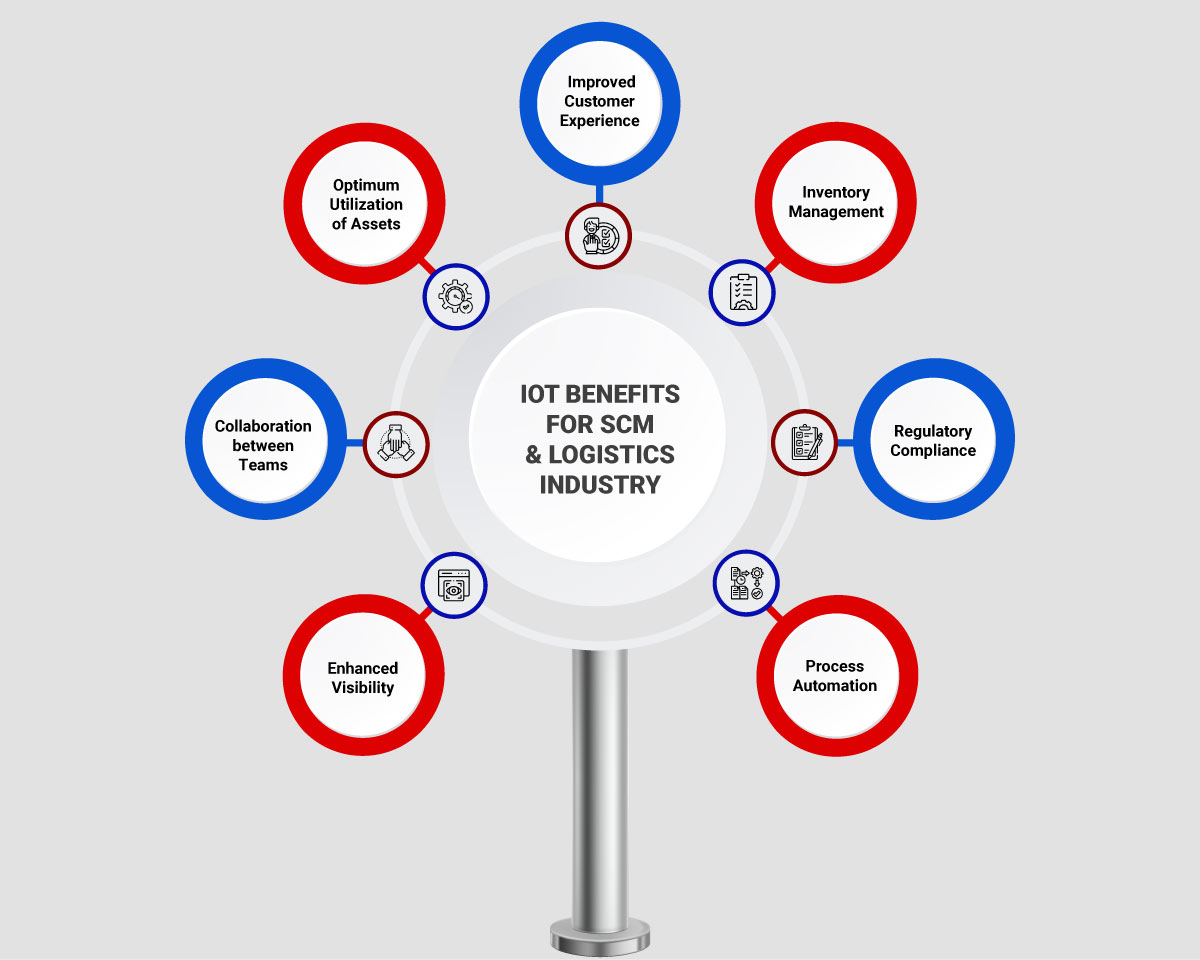

Benefits of IoT in Supply Chain Management & Logistics

IoT is transforming complex supply chains into connected networks. The data collected by IoT devices help streamline tasks across the supply chain & take timely corrective measures to minimize or eliminate losses.

Here are some of the advantages of using IoT in Supply Chain & Logistics:

- Enhanced Visibility: It is across every stage of the supply chain, from manufacturing to retail. Raw material suppliers use IoT devices to gather data on factors influencing the timely & quality availability of deliverables. For instance, monitoring crop health for agriculture, logging operations for forestry, and livestock health for farming. Similarly, retailers use IoT to enhance the accuracy of goods pickup & increase material handling efficiency. They also benefit from tracking products across shelves for better inventory management and monitoring store traffic for better display & space utilization.

- Better Collaboration between Teams: Complex value chains often break into a series of data silos. Bottlenecks in the supply chain appear as teams refer to different data & are not on the same page. It is especially true with enterprises utilizing legacy systems with low or no data analysis capabilities. As IoT-based solutions also use cloud & data analytics capabilities, they break the data silos giving one version of the truth to all teams across the value chain. It enhances collaboration between the teams & in turn, facilitates quick resolution of issues.

- Optimum Utilization of Assets: IoT brings the much-needed connectivity to allow supply chain & logistics managers to optimize their fleets. They can plan more intelligent routes, identify delayed assets, monitor asset efficiency & fine-tune operations to increase delivery numbers. Further Machine Learning (ML) & AI-based processes help decipher the data provided by IoT devices and carry out predictive analytics. It allows better fleet maintenance, cargo management, vehicle monitoring & environment-conscious operations. Therefore, IoT offers enhanced visibility, savings, manageability, security, reduced downtime, and optimal use of assets.

- Improved Customer Experience: The smooth functioning of supply chains results in the managers meeting their end customer expectations in terms of the time & quality of deliveries. It enhances customer experience and, in turn, results in business growth. Further, they can even monitor shipments & products in real-time and accurately estimate the delivery time. By identifying delivery issues early, they can take corrective measures. They can also make alternate delivery arrangements to meet service-level agreements.

- Better Inventory Management: Inventory tracking & control is an essential aspect of supply chain & warehouse management. IoT devices collect & analyze stock levels and inventory positions for better management & optimization. IoT-enabled inventory tracking systems provide accurate data to supply chain managers, including distribution & transportation companies. It helps them smoothly manage the supply chain by tracking product availability & limit orders accordingly while preventing avoidable shortages.

- Regulatory Compliance: Businesses need to comply with required local legal & compliance requirements. IoT helps businesses adhere to regulatory compliance & litigation prevention in terms of managing mandatory paperwork and complying with legislation. An IoT-based solution provides a digital audit trail with accurate timestamps while providing swift & correct reports.

- Process Automation: Smart logistics solutions help businesses automate the most time-consuming & complicated documentation tasks. For instance, they are processing a bill of lading that the carrier issues to acknowledge the cargo receipt for the shipment. Warehouse automation is another considerable benefit of IoT for the supply chain management. It reduces human effort & errors while enhancing the efficiency & accuracy of operations.

Industry IoT Use Cases in Supply Chain & Logistics

Industry leaders are already combining IoT with core processes of the Supply Chain & Logistics Industry. Here are a few noteworthy industry applications:

Smart Warehouse: A smart warehouse uses machines and computers to complete everyday operations like shifting racks, labeling, and more. It was something humans previously performed.

- Amazon uses robots to perform all tasks that require rushing around and lifting heavy loads. It has QR codes embedded on the warehouse floor to assist robots in finding their way.

- Humans work alongside the robots but focus on tasks requiring dexterity & problem-solving.

- The IoT-enabled automation has helped Amazon store 50% more stock & retrieve that inventory 3x faster. Also, its fulfillment cost is reduced by 40%.

Remote Container Management: The RCM (Remote container management) technology allows monitoring of the current location of refrigerated containers and the temperature & humidity inside the container. It shows the power connection status anytime on board the vessel and during transportation.

- Leading Danish shipping and logistics company, Maersk, utilizes Remote Container Management to reduce or prevent spoilage of perishable cargo and reduce resource wastage.

- It monitors weather & other environmental conditions to plan better & implement transportation.

Predictive Maintenance Solution: It helps optimize equipment maintenance by using sensors, AI & data science. Thus it minimizes the minimal maintenance costs and maximizes uptime.

- For their engine plant in Lyon, France, Volvo Group, uses a IoT-based predictive maintenance solution they call Fluid Monitoring.

- It monitors the five engine test cells in the Group Truck Operations (GTO) factory.

- The system alerts the maintenance team before anything goes wrong. Hence they could avoid pausing the engine tests. It saves them a lot of time & money.

You can also read our blog on the trends & use cases of IoT across industries to know more.

Why Partner with Rishabh Software for IoT Development?

We have experience providing custom software solutions to the Supply Chain Management & Logistics industry. We combine it with our IoT development capabilities to deliver technology solutions that meet the modern-day supply chain & logistics requirements.

Our team has a working knowledge of connectivity technologies, protocols & standards, IoT platforms, sensors, and supportive development frameworks & languages.

Here’s a use case of the Internet of Things and Supply Chain Management from our experience;

Case Study: ELD Fleet Management Mobile App with IoT Capabilities

One of our US clients for their fleet operations wanted to develop a system to live track their cargo & commercial drivers. Their objective was two-fold:

-

- Meeting Regulatory Compliance for the Federal Motor Carrier Safety Administration (FMCSA) that governs Hours of Service (HOS)

- Getting Visibility into Operations and digitizing paper logs for Records of Duty Status (RODS) for all commercial drivers.

As their IoT technology consulting and development partner, we supported them with a fleet management mobile solution. Today, the application allows fleet owners & operators to monitor, manage driver logs, and conduct vehicle inspections as needed.

Our team executed the project in two phases.

Phase 1: Mobile app creation to interact with IoT sensors (On-board Diagnostics (OBD) Port II) for GPS tracking & alerts

We utilized Xamarin to develop the electronic logging device app solution and integrated sensors, device functions, data, network-managed services, mapping & GPS functionality. Our team created a backend web console to track and map data points.

Phase 2: Data reporting in a standardized format that can be transmitted to law enforcement in prescribed ways (wireless web services, USB, or Bluetooth 2.0).

We integrated On-board Diagnostics (OBD) Port II to the ELD solution to capture the vehicle’s health & driver’s duty status & send this data to the mobile app. Our team utilized ELD hardware – Serial Port Profile (SPP) and Generic Attribute Profile (GATT) Bluetooth profiles to enable seamless communication between devices.The solution included features like:

- Real-time tracking & recording of the vehicle’s duty status, load records, and data points to send updates on vehicle inspection for necessary maintenance

- Driver’s daily logs for fleet managers to view & download reports

- Online & accurate driver & load scheduling for fleet managers

- Automated & instant notifications to both drivers and dispatchers

Key takeaways;

- 100% automation of DVIR (Driver Vehicle Inspection Reporting)

- 2x optimization of driver & fleet efficiency

- 62% increase in fleet profitability

Concluding Thoughts

As discussed, Internet of Things applications in supply chain management & logistics has a vast range of applications. It facilitates the tracking and monitoring of goods, brings more transparency to the communication process, and supports planning precision. Businesses are already recognizing the benefits that IoT provides in enhancing visibility & improving the maturity of their supply chain. As the IoT technology advances further, there will be more & fast implementation

And investing in an IoT-based platform is an excellent option for small and large companies. However, an important point is their clear objective about what they need the technology to accomplish. Therefore, onboarding a skilled team for the design and development stage is also crucial. It helps to ensure your IoT solution for the supply chain meets modern tech trends and is fully functional. We at Rishabh Software have the experience to deliver IoT development services to companies of all sizes, from start-ups to enterprises. We can handle your project from starch or continue with an ongoing project.