Unexpected equipment downtime can cause serious headaches for manufacturing organizations. If critical machinery suddenly breaks – the results could range from production slowdowns to complete functional failures. Preventative maintenance, or strategies such as scheduled maintenance checks and conditioned-based maintenance, may no longer be enough in a fast-paced, complex environment for manufacturing, retail, healthcare, logistics, and operations.

That is where the role of AI in predictive maintenance is fast gaining critical significance. Integrating advanced technologies like AI in predictive maintenance can empower businesses to proactively detect equipment failures, optimize maintenance schedules, and reduce unexcepted downtime, ultimately improving efficiency and cost management.

The market for AI in predictive maintenance is expected to grow significantly, from $723 million to $2,306 million by 2033[1], highlighting the increasing importance of AI-driven predictive maintenance solutions in minimizing downtime and optimizing operations. Keep reading this blog post to learn in-depth about predictive maintenance using AI benefits, roles, steps to implement, and key components.

Role of AI in Predictive Maintenance: Key Technologies and Their Impact

Traditionally, maintenance schedules have been reactive and are either based on estimates of a machine’s lifetime or based on recommendations from the original equipment manufacturer. Integrating AI in predictive maintenance allows your enterprise to leverage data-driven insights on how equipment or assets are performing and when they will break down.

Manufacturers seek to integrate AI into predictive maintenance strategies to enhance the efficiency and quality of their production lines and significantly improve system reliability. With sophisticated AI-based algorithms, models, and expertise, a predictive maintenance system makes manufacturing operations more reliable and efficient. AI-based predictive maintenance helps promptly identify inefficiencies in equipment and machinery functions, triggering alerts for necessary maintenance. This reduces the probability of failure, increases mean-time-to-failure (MTTF), and mean time between failure (MTBF), and eliminates unnecessary maintenance operations, leading to reduced downtime.

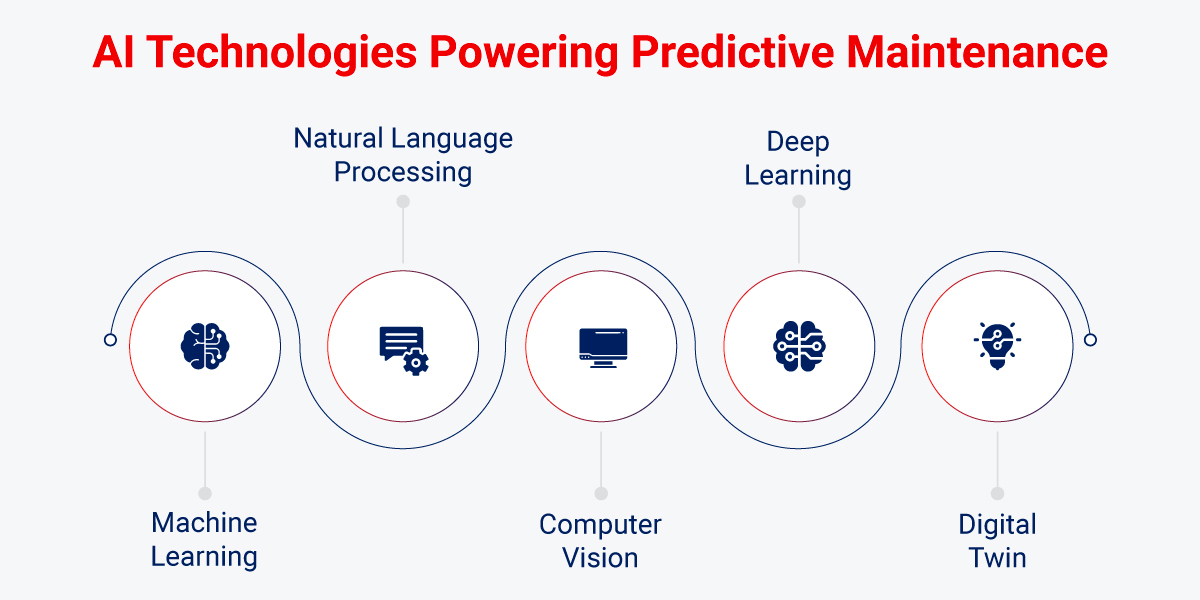

AI Technologies Driving Predictive Maintenance:

- Machine Learning: Various models are built with machine learning capabilities, making predictive maintenance more accurate and improving maintenance strategies for manufacturing equipment. Time series analysis on historical production data, models like ARIMA, SARIMA, LSTM, and GRU for optimal results. Linear regression, polynomial regression, and support vector regression help predict continuous values such as equipment wear. Other models include SVM, isolation forest for anomaly detection, Convolutional neural networks (CNNs) for complex data handling in visual inspection, and more.

- Natural Language Processing: The key role of NLP in predictive maintenance is to make the job of extracting information from a large set of data easier for identifying potential risks. It helps in fault diagnosis and contributes to the maintenance of historical analysis and expert knowledge capture for more efficient troubleshooting

- Computer Vision: AI-powered computer vision plays a crucial role in predictive maintenance. It enables real-time visual inspection and equipment monitoring. Analyzing visual data from AI-powered cameras and sensors, computer vision can help identify early signs of equipment failure.

- Deep Learning: This subset of machine learning quickly learns complex patterns from historical manufacturing data sets in order to promptly detect and respond to anomalies. Deep learning concepts like feature learning, non-linear relationships, and hierarchical representation boost the predictive maintenance process by identifying early signs of potential equipment failure.

- Digital Twin: As a capability, a digital twin creates an exact virtual replica of any physical asset or production line. In predictive maintenance, this capability of the digital twin enables real-time monitoring of equipment, allows for scenario testing to develop better maintenance strategies, and prevents inefficiencies in the production process.

Traditional Maintenance Vs Predictive Maintenance

| Aspect | Traditional Maintenance (Challenges) | AI-Based Predictive Maintenance (Solutions) |

| Maintenance Approach | Reactive or scheduled maintenance is often performed after a failure or based on fixed intervals. | It is a proactive, data-driven approach that uses AI algorithms to predict issues, leading to optimized maintenance schedules. |

| Downtime | The risk level is high due to unexpected breakdowns caused by unforeseen equipment failures. | Reduced risk of unexpected asset failure through early detection of potential issues and equipment failures. |

| Cost Efficiency | High maintenance costs due to frequent inspections, unnecessary replacements, unplanned downtime, and emergency repairs. | Lower overall costs by minimizing maintenance activities and avoiding emergency repairs through precise predictions. |

| Resource Utilization | Inefficient use of resources, such as maintenance tasks, is often performed on equipment that doesn’t require it. | Optimized resource allocation by targeting maintenance efforts based on actual equipment condition and performance. |

| Mean Time Between Failures (MTBF) | Lower MTBF due to lack of capability to get insights on equipment performance and avoid breakdown | It helps in increasing MTBF due to technology integration to predict equipment failure. |

| Mean Time to Repair (MTTR) | Lack of information requires more time for fault diagnosis and repair, sometimes resulting in a longer Mean Time to Repair (MTTR) | Lower MTTR because of advanced fault detection and predictive alerts, which provide enough time for repairs. |

| Data Utilization | The traditional approach relies on manual inspection and previously conducted diagnosis and repairs. It does not require a large dataset. | Predictive maintenance using AI empowers experts to leverage real-time data from attached sensors, while the implementation of advanced analytics provides accurate and timely insights into equipment health. |

| Scalability | It is challenging to scale as the need for manual checks and reactive maintenance grows with more equipment. | Easily scalable across multiple assets and locations using centralized AI models and IoT-enabled sensors. |

| Operational Efficiency | Reduced operational efficiency due to unexpected breakdowns, manual interventions, and frequent disruptions. | Enhanced operational efficiency through automated monitoring, tracking, predictive alerts, and streamlined maintenance planning through a pre-scheduling process. |

| Safety and Compliance | Increased risk of safety hazards and non-compliance with regulations due to unexpected failures and delayed maintenance. | Enhanced safety and compliance through continuous monitoring and timely interventions, reducing the likelihood of accidents. |

How does AI in Predictive Maintenance Work, and What Are Its Key Components?

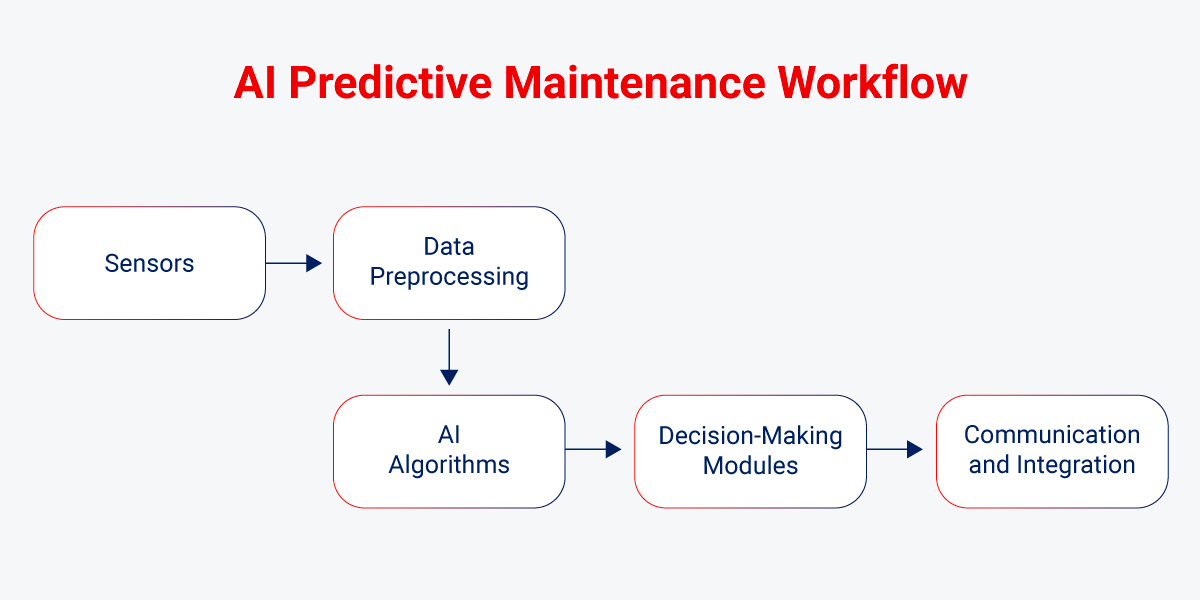

An AI-based predictive maintenance system enables condition-based monitoring to manage the performance and health of manufacturing assets. It involves multiple stages and a systematic approach, including data collection, processing, establishing predefined rules, analysis, and data-driven decision-making. The following key components drive the efficiency of an AI-enabled predictive maintenance system in manufacturing.

Key Components of AI in Predictive Maintenance:

Predictive maintenance with AI typically has six major components. Let’s discuss how each is exactly linked and its role in AI in the predictive maintenance process:

- Sensors: They serve as the primary data collection devices in AI-based predictive maintenance for monitoring various parameters like temperature, pressure, and vibration. These real-time data are all related to assets’ health and performance in order to form an analysis set.

- Data Processing: Raw data obtained from sensors on the structural health of assets, equipment, or machinery often contains inconsistencies. The data processing stage analyzes this raw data to generate meaningful insights, including subprocesses like data cleaning, normalization, and handling missing data to yield high-quality results.

- AI Algorithm: Subsets like machine learning and deep learning are the core of overall AI and predictive maintenance They are capable of learning over time and play a critical role in separating signal and data points from noise. It includes predefined rules and instructions that analyze data in order to detect patterns, identify gaps, predict failures or breakdowns and, identify the probability of anomalies, and more.

- Decision-Making Module: This module is instrumental in further processing AI-generated insights and suggests predictions. It is known for its ideal recommendations, actions, scheduling upkeep, and adjustments.

- Integration & Communication: The component ensures a seamless flow of information across the organization. It majorly involves communication and interaction between various stakeholders, such as maintenance personnel, management, and experts.

What are the Key Benefits of Using AI in Predictive Maintenance?

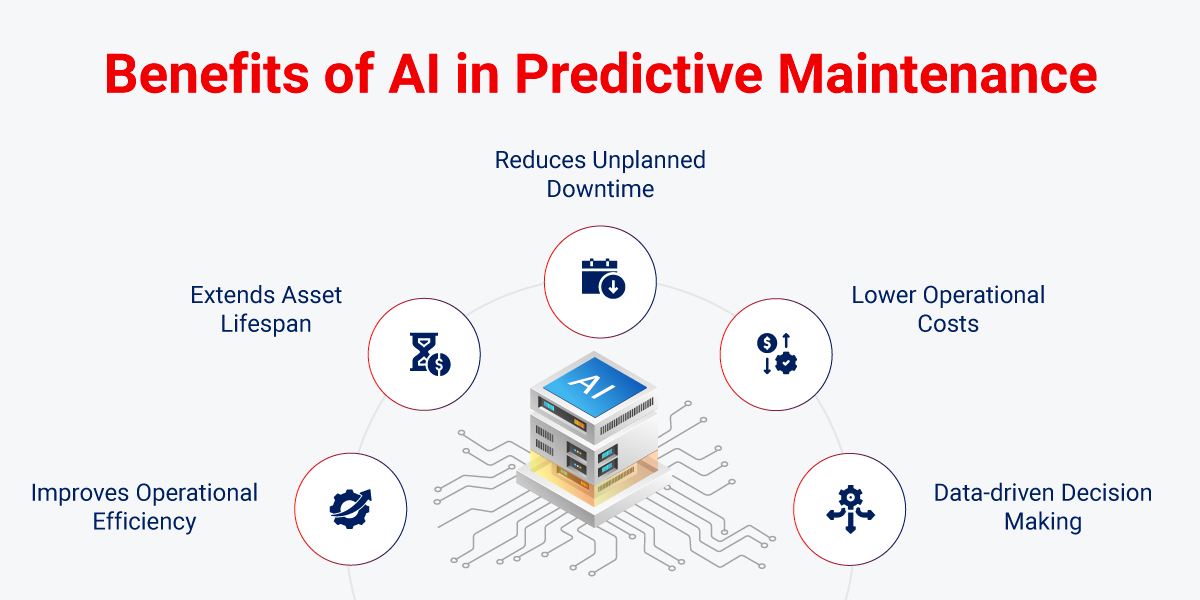

Integrating artificial intelligence in predictive maintenance gives manufacturing businesses numerous advantages, including operation streamlining, cost-effectiveness, efficient resource management, and more. Let’s explore the benefits of using AI for predictive maintenance in manufacturing.

- Improves Operational Efficiency: Predictive maintenance with the use of artificial intelligence allows for intelligent analysis of equipment’s behavior. This enables businesses to schedule for maintenance, hence avoiding downtime due to failure. Additionally, AI helps determine which vital maintenance activities require an investment of resources and prioritizes them correctly. This cuts on wastage and increases operational efficiency. Integrating AI also promotes data analysis, better decision-making, and improved operational effectiveness.

- Extends Asset’s Lifespan: AI has the ability to match patterns and identify degradation while assets and equipment are in operation, ensuring optimal operational conditions. Taking action at the right time, before a breakdown occurs, helps keep machinery in good health for a longer period.

- Reduces Unplanned Downtime: AI algorithms, like anomaly detection and predictive modeling, use real-time sensor data to foresee potential equipment failures. Whenever any abnormal condition occurs, the predictive maintenance system automatically sends alerts via email, message, or dedicated apps, along with a visual representation of the issue. The presentation of a visual dashboard created using technologies like Power BI or Tableau, as well as data visualization, further enables quick response.

- Lower Operational Costs: Machine learning techniques, such as regression analysis and classification algorithms, play crucial roles in optimizing maintenance operations by predicting the best timing for repairs. It avoids costly breakdowns and minimizes operational halts. AI-driven features like anomaly detection, root cause analysis, and failure pattern recognition are utilized highly for earlier detection of issues. Digital twins also contribute to minimizing disruption, keeping operations running smoothly, and reducing overall costs.

- Enables Data-driven Decision Making: AI for predictive maintenance uses multiple techniques, such as neural networks and decision trees, that perform structure and unstructured data analysis to generate more insightful information. These data help businesses to make better decisions in every aspect, such as fine-tuning maintenance schedules, optimizing resource allocation, and reducing unnecessary interventions.

Applications of AI for Predictive Maintenance

Business leaders continuously trust in the latest technologies and emphasize their efforts to implement AI in all possible areas. One such area is predictive maintenance. Let’s explore how predictive maintenance with AI can be used:

- Manufacturing Equipment Monitoring: In manufacturing environments, where machines like CNC machines, conveyors, and robotics operate around the clock, AI-driven predictive maintenance can play a crucial role. After collecting data from these machinery, AI algorithms and machine learning modules work further by analyzing parts to detect anomalies and deviations. Manufacturers can extend the lifespan of equipment without interruptions to production.

- Healthcare Equipment Monitoring: In the process of effective management of medical devices like MRI machines, ventilators, CT scanners, and ultrasound equipment, AI and predictive maintenance can have a transformative role. Healthcare service providers can leverage advanced algorithms for data analysis and performance logs using anomaly detection, regression analysis, and time-series forecasting to identify the ideal predictive maintenance needs. It helps clinics and large health service providers to keep equipment operational in critical condition, with fewer disruptions, optimal resource allocation, and enhanced overall patient care.

- Oil and Gas Pipeline Monitoring: AI helps in identifying early signs of corrosion, leaks, or pressure changes. Natural language processing (NLP) and computer vision analyze data from sensors installed on various pipelines. These AI technologies can also be applied to analyze inspection reports and visual data from drones or cameras. This powerful tool allows maintenance teams to identify and eliminate risks before they escalate into problems that could affect the environment and require significant operational investments.

- Smart Grid Management: Integrating AI in smart grids allows them to make forecasts on likely failures in transformers, circuit breakers, and power lines by analyzing data such as load pattern, climate, and condition of the equipment. This assists utility companies in scheduling maintenance and avoiding effective blackouts and general operational expenses.

- Fleet Management: AI-driven predictive maintenance can be used in fleet management to closely monitor and track vehicles’ condition on various routes, speed, tire health, fuel efficiency, and other factors. This information helps predict the maintenance time needed. It reduces breakdown probability, improves fuel efficiency, and prolongs the lifespan of vehicles.

Steps to Implement AI-Based Predictive Maintenance

1. Define Objectives: Choose measurable goals for the AI system to work with. For example, one might target minimizing the time of equipment downtime or planning maintenance schedules.

2. Collect Data: Collect data from the sensors, maintenance logs, and operating systems. Ensure that all information received or apprehended is accurate and, where possible, that it covers all relevant information.

3. Preprocess Data: This step includes removing and dealing with empty values in the data set, standardizing formats, and removing or minimizing data inconsistencies.

4. Develop AI Models: Select and develop AI models like machine learning algorithms or artificial neural networks. Train these models on historical performance data to identify patterns of equipment failures.

5. Deploy AI Models and Integrate: Implement AI models within the production setting and embed the AI approaches with the current monitoring and maintenance processes.

6. Monitor and Optimize: Continuously monitor the performance of the AI system, adjust the models based on the feedback received, and modify the measures for maintaining the system to achieve better outcomes.

How Rishabh Software Leverages AI in Predictive Maintenance to Drive Manufacturing Excellence

Our team of 1,000+ professionals at Rishabh Software has helped clients integrate the latest technologies, like AI, into processes to transform various industries, such as manufacturing, retail, and finance. We help modernize processes, infrastructure, and products for long-term sustainability. Our full-cycle Artificial Intelligence development services, supported by dedicated AI/ML engineers, are designed to develop and operate advanced, industrial-scale enterprise AI applications. Our exceptional collaboration model creates a seamless bridge to success.

At Rishabh Software, we offer predictive maintenance solutions for manufacturing with AI, leveraging the latest IoT technologies, advanced data analytics, business intelligence, data science, and more. Our approach to refining predictive capabilities empowers businesses to adopt data-driven processes and IoT consulting services to ensure safer maintenance practices. With our unique model-driven architecture, we deliver tailored solutions that apply out-of-the-box and configurable AI algorithms, providing businesses with the flexibility and intelligence needed to minimize downtime and optimize operational efficiency.

Frequently Asked Questions

Q: What types of data are used in AI-driven predictive maintenance?

A: There are different types of data used for AI-driven predictive maintenance, including are

- Real-time data (Temperature, Vibration, and Pressure),

- Historical Maintenance data,

- Operating data (Usage Hours and Load conditions),

- Environmental data (Temperature and Humidity).

It also contains failure data, real-time performance data, data from a camera or drone, and process data. Thanks to such data, it becomes possible to determine equipment failures, set optimal intervals for maintenance, and improve the overall efficiency of the facility’s functioning in general.

Q: Which industries benefit most from AI in predictive maintenance?

A: Here is a list of industries that benefitted the most from AI-based predictive maintenance:

- Manufacturing

- Healthcare

- Energy and Utilities

- Transportation and Logistics

- Mining and many others

Q: What are the future trends of AI in predictive maintenance?

A: Future trends of AI in predictive maintenance include:

- Advanced Machine Learning Models

- Integration with IoT for real-time data collection

- Edge Computing for faster data processing

- Integration with Augmented Reality (AR)

- IoT predictive maintenance solutions for enhanced efficiency and accuracy

Q: What are the key AI methods used in predictive maintenance to make predictions?

A: AI uses various methods to make predictions and analyze data. Here is a list of different data.

- Regression Analysis

- Classification Algorithms

- Time-Series Analysis

- Anomaly Detection

- Ensemble Methods

- Bayesian Methods

Footnotes:

1. https://market.us/report/ai-in-predictive-maintenance-market/